1.Romeo ESP32-S3简介

Romeo ESP32-S3开发板是专为机器人项目设计的高性能开发板。该开发板搭载了ESP32-S3-WROOM-1U-N16R8模组,为机器人项目提供强大的计算能力和无线通讯功能。同时,Romeo ESP32-S3还配备了4路2.5A直流电机驱动,无需额外添加电机驱动板即可轻松制作机器人项目。

该开发板配备了一颗高品质的OV2640摄像头,拥有200万像素和68°视场角,支持最高1600*1200分辨率,为机器人提供了视觉输入设备。

ESP32-S3-WROOM-1U-N16R8模组内置16MB Flash和8MB PSRAM,可存储更多代码和数据。其搭载的ESP32-S3芯片具备强大的神经网络运算和信号处理能力,使机器人更加智能。

Romeo ESP32-S3支持Wi-Fi和Bluetooth 5 (LE)双模通讯,可实现无线控制机器人和图像传输的功能。

可以在Arduino IDE、ESP-IDF、MicroPython等环境下对Romeo ESP32-S3进行编程,C语言、python都可以轻松的操纵硬件。

注意:烧录代码前,请按住BOOT,点击复位按键,然后松开BOOT使开发板进入下载模式

2.产品特性

- 四路2.5A大电流H桥电机驱动

- 支持PH/EN控制模式和PWM控制模式

- 多路5V电源输出,方便驱动舵机

- 独立摄像头供电电路

- 板载GDI显示、DVP摄像头、USB、MicroSD卡接口

- 板载ESP32-S3-1U-N16R8 (16MB FLASH / 8MB PSRAM)

- 支持Wi-Fi 和 Bluetooth 5 (LE) 双模通讯

3.产品参数

基本参数

- Type-C输入电压: 5V DC

- 模组工作电压: 3.3V

- VIN输入电压:7-24V

- VM输入电压:5-24V

- 5V电源最大输出电流:2A

- 电机驱动能力:2.5A

- 工作温度:0~60℃

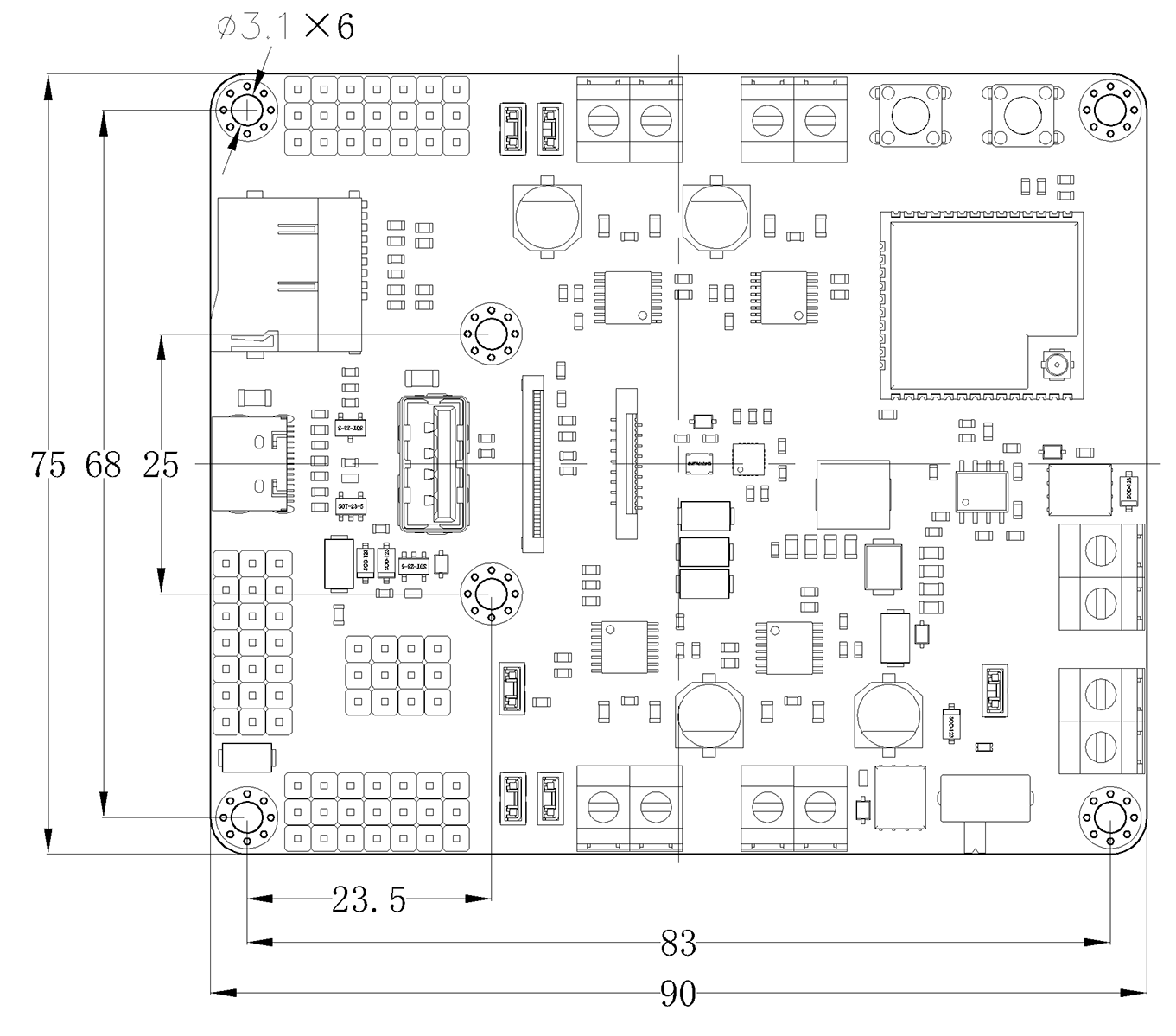

- 模块尺寸:75*90mm

硬件信息

- 处理器:Xtensa® 双核32位LX7微处理器

- 主频:240 MHz

- SRAM:512KB

- ROM:384KB

- Flash:16MB

- PSRAM: 8MB

- RTC SRAM:16KB

- USB: USB 2.0 OTG全速接口

WIFI

- WIFI协议:IEEE 802.11b/g/n

- WIFI频宽: 2.4 GHz 频带支持 20 MHz 和 40 MHz 频宽

- WIFI模式:Station 模式、SoftAP 模式、SoftAP+Station 模式和混杂模式

- WIFI频率:2.4GHz

- 帧聚合: TX/RX A-MPDU, TX/RX A-MSDU

蓝牙

- 蓝牙协议:Bluetooth 5、Bluetooth mesh

- 蓝牙频率:125 Kbps、500 Kbps、1 Mbps、2 Mbps

接口引脚

- 数字I/O x27

- LED PWM 控制器 8个通道

- SPI x2

- UART x3

- I2C x2

- I2S x2

- 红外收发器:发送通道 x5、接收通道 x5

- 2 × 12 位 SAR ADC, 20个通道

- DMA 控制器,5 个接收通道和 5 个发送通道

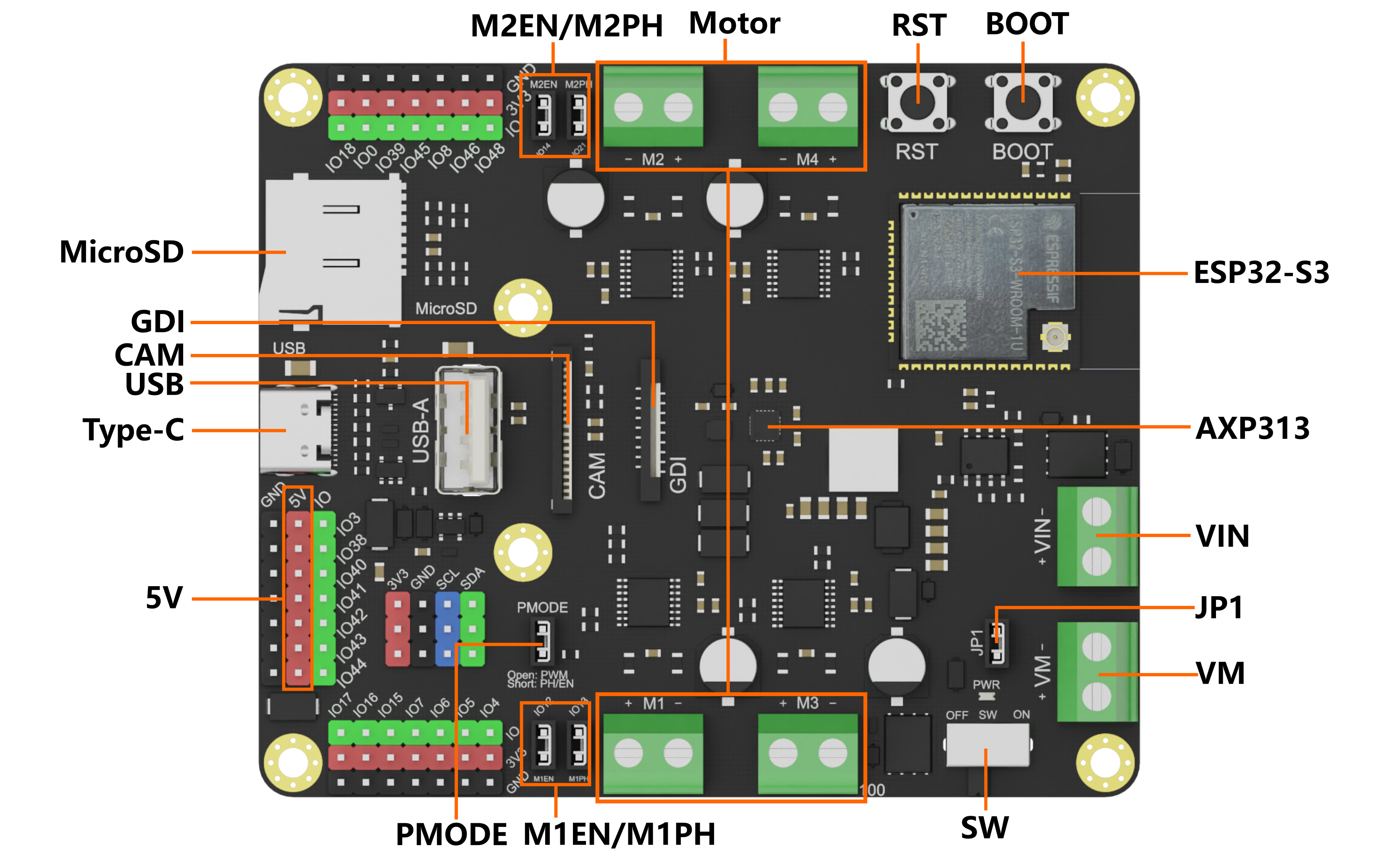

4.板载资源示意

- Type-C:5V输入

- 5V:5V电源输出

- VIN:7-24V, 主控电源输入

- VM:5-24V, 电机电源输入

- JP1:电源切换跳线帽,短接时控制器和电机共用电源

- SW:电源控制开关

- PMODE: 电机驱动模式跳线帽,短接时为PH/EN控制模式,断开时为PWM控制模式

- Motor:电机接线端子

- ESP32-S3模组:乐鑫公司推出的ESP32-S3模组

- M1EN/M1PH:M1电机驱动跳线

- M2EN/M2PH:M2电机驱动跳线

- RST:复位按键

- BOOT:BOOT按键

- AXP313A:电源管理芯片

- GDI:GDI显示屏接口

- CAM:DVP摄像头接口

- USB:USB接口,可接USB外设

- MicroSD:TF卡卡槽

5.引脚概述

GPIO分配表

电机引脚

| PINS | Romeo ESP32-S3 PINS |

|---|---|

| M1_EN/IN1 | 12 |

| M1_PH/IN2 | 13 |

| M2_EN/IN1 | 14 |

| M2_PH/IN2 | 21 |

| M3_EN/IN1 | 9 |

| M3_PH/IN2 | 10 |

| M4_EN/IN1 | 47 |

| M4_PH/IN2 | 11 |

GDI显示接口

此接口为DFRbot专用GDI显示屏接口,使用18pin-FPC线连接连接屏幕,连接屏幕更加便捷。

以下是GDI接口使用的引脚列表

| FPC PINS | Romeo ESP32-S3 PINS | Description |

|---|---|---|

| VCC | 3V3 | 3.3V |

| LCD_BL | 21 | 背光 |

| GND | GND | GND |

| SCLK | 17/SCK | SPI时钟 |

| MOSI | 15/MOSI | 主机输出,从机输入 |

| MISO | 16/MISO | 主机输入,从机输出 |

| LCD_DC | 3 | 数据/命令 |

| LCD_RST | 38 | 复位 |

| LCD_CS | 18 | TFT片选 |

| SD_CS | 0 | SD卡片选 |

| FCS | 7 | 字库片选 |

| TCS | 12 | 触摸片选 |

| SCL | 2 | I2C时钟 |

| SDA | 1 | I2C数据 |

| INT | 13 | INT |

| BUSY | 14 | 防撕裂引脚 |

| X1 | NC | 自定义引脚1 |

| X2 | NC | 自定义引脚2 |

使用FPC链接屏幕时根据GDL demo配置所需对应的引脚号即可,通常只需要根据不同主控配置三个引脚

支持GDI的显示屏:

- 1.54" 240x240 IPS广视角TFT显示屏

- 1.8”128x160 IPS TFT LCD 显示屏

- 2.0" 320x240 IPS广视角TFT显示屏

- 2.8" 320x240 IPS TFT电阻触摸显示屏

- 3.5" 480x320 IPS TFT电容触摸显示屏

- 1.51”OLED 透明屏幕

CAM接口

此接口为DVP摄像头接口,兼容OV2640和OV7725摄像头

以下是DVP摄像头接口使用的引脚列表

注意:使用摄像头时需使用”axp.enableCameraPower(axp.eOV2640);“打开摄像头电源

| CAM PINS | Romeo ESP32-S3 PINS | Description |

|---|---|---|

| NC | NC | NC |

| AGND | / | 模拟地 |

| SDA | 1/SDA | I2C数据 |

| AVDD | / | AXP313A可控电源 |

| SCL | 2/SCL | I2C时钟 |

| RST | / | 已上拉到DOVDD |

| VSYNC | 6/A2 | 帧同步信号 |

| PWDN | / | 已下拉 |

| HREF | 42 | 行同步信号 |

| DVDD | / | AXP313A可控电源 |

| DOVDD | / | AXP313A可控电源 |

| D9 | 48 | DATA 9 |

| XMCLK | 45 | 时钟信号 |

| D8 | 46 | DATA 8 |

| DGND | GND | 数字地 |

| D7 | 8/A3 | DATA 7 |

| PCLK | 5/A1 | 像素时钟信号 |

| D6 | 7/D5 | DATA 6 |

| D2 | 39 | DATA 2 |

| D5 | 4/A0 | DATA 5 |

| D3 | 40 | DATA 3 |

| D4 | 41 | DATA 4 |

| NC | NC | NC |

| NC | NC | NC |

6.示例代码

基础使用教程请看FireBeetle ESP32-S3教程

6.1 EN/PH模式驱动电机

PH/EN 控制模式真值表

| EN | PH | OUT1 | OUT2 | 说明 |

|---|---|---|---|---|

| 0 | X | L | L | 制动(低侧慢速衰减) |

| 1 | 0 | L | H | 后退 (OUT2 → OUT1) |

| 1 | 1 | H | L | 前进 (OUT1 → OUT2) |

6.1.1 驱动直流电机

/**

*@brief motorSpeeddetectionbyPH_EN.ino

*@ 在PH/EN模式下的电机驱动程序

*/

#include "driver/mcpwm.h"

#include "soc/mcpwm_struct.h"

#include "soc/mcpwm_reg.h"

//IO12->M1_IN1

//IO13->M1_IN2

#define MOTOR_STEP_PIN 12

#define MOTOR_DIRECTION_PIN 13

//初始化需要产生PWM信号的引脚

void mcpwm_init(void)

{

/**

* @brief This function initializes each gpio signal for MCPWM

* @note

* This function initializes one gpio at a time.

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param io_signal set MCPWM signals, each MCPWM unit has 6 output(MCPWMXA, MCPWMXB) and 9 input(SYNC_X, FAULT_X, CAP_X)

* 'X' is timer_num(0-2)

* @param gpio_num set this to configure gpio for MCPWM, if you want to use gpio16, gpio_num = 16

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0A,MOTOR_STEP_PIN);//绑定需要输出PWM的引脚到PWM通道上面

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0B,MOTOR_DIRECTION_PIN);

//配置mcpwm信息

mcpwm_config_t pwm_config;

pwm_config.frequency = 1000;/*!<Set frequency of MCPWM in Hz*/

pwm_config.cmpr_a = 0;/*!<Set % duty cycle for operator a(MCPWMXA), i.e for 62.3% duty cycle, duty_a = 62.3*/

pwm_config.cmpr_b = 0;/*!<Set % duty cycle for operator b(MCPWMXB), i.e for 48% duty cycle, duty_b = 48.0*/

pwm_config.counter_mode/*!<Set type of MCPWM counter*/ = MCPWM_UP_COUNTER/*!<For asymmetric MCPWM*/;

pwm_config.duty_mode/*!<Set type of duty cycle*/ = MCPWM_DUTY_MODE_0/*!<Active high duty, i.e. duty cycle proportional to high time for asymmetric MCPWM*/;

/**

* @brief Initialize MCPWM parameters

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers.

* @param mcpwm_conf configure structure mcpwm_config_t

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_0,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

}

void advance(/*范围:0~100*/uint8_t speed)

{

/**

* @brief Use this function to set MCPWM signal high

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the operator(MCPWMXA/MCPWMXB), 'x' is timer number selected

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);//给MOTOR_STEP_PIN一个持续的高电平

/**

* @brief Set duty either active high or active low(out of phase/inverted)

* @note

* Call this function every time after mcpwm_set_signal_high or mcpwm_set_signal_low to resume with previously set duty cycle

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the generator(MCPWMXA/MCPWMXB), 'x' is operator number selected

* @param duty_type set active low or active high duty type

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

/**

* @brief Set duty cycle of each operator(MCPWMXA/MCPWMXB)

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the generator(MCPWMXA/MCPWMXB), 'X' is operator number selected

* @param duty set duty cycle in %(i.e for 62.3% duty cycle, duty = 62.3) of each operator

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//MOTOR_DIRECTION_PIN引脚输出占空比为“speed”的PWM波

}

void retreat(/*范围:0~100*/uint8_t speed)

{

//给MOTOR_STEP_PIN一个持续的低电平

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

//MOTOR_DIRECTION_PIN引脚输出占空比为“speed”的PWM波

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);

}

void breake(void)

{

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

}

void setup() {

mcpwm_init();

}

void loop() {

advance(70);

delay(2000);

retreat(30);

delay(2000);

breake();

delay(2000);

}

6.1.2 驱动带编码器直流电机

通过PID控制电机转动速度

/**

*@brief motorSpeeddetectionbyPH_ENwithencoder.ino

*@ 在PWM模式下的电机驱动程序(带编码器)

*/

#include "driver/mcpwm.h"

#include "soc/mcpwm_struct.h"

#include "soc/mcpwm_reg.h"

#include <PID_v1.h>

//IO12->M1_IN1

//IO13->M1_IN2

#define MOTOR_STEP_PIN 12

#define MOTOR_DIRECTION_PIN 13

const byte encoder0pinA = 3;//A pin -> the interrupt pin 3

const byte encoder0pinB = 4;//B pin -> the digital pin 4

byte encoder0PinALast;

double duration,abs_duration;//the number of the pulses

boolean Direction;//the rotation direction

boolean result;

double val_output;//用于提供给电机PWM功率值。

double Setpoint;

double Kp=0.6, Ki=5, Kd=0;

PID myPID(&abs_duration, &val_output, &Setpoint, Kp, Ki, Kd, DIRECT);

//初始化需要产生PWM信号的引脚

void mcpwm_init(void)

{

/**

* @brief This function initializes each gpio signal for MCPWM

* @note

* This function initializes one gpio at a time.

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param io_signal set MCPWM signals, each MCPWM unit has 6 output(MCPWMXA, MCPWMXB) and 9 input(SYNC_X, FAULT_X, CAP_X)

* 'X' is timer_num(0-2)

* @param gpio_num set this to configure gpio for MCPWM, if you want to use gpio16, gpio_num = 16

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0A,MOTOR_STEP_PIN);//绑定需要输出PWM的引脚到PWM通道上面

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0B,MOTOR_DIRECTION_PIN);

//配置mcpwm信息

mcpwm_config_t pwm_config;

pwm_config.frequency = 1000;/*!<Set frequency of MCPWM in Hz*/

pwm_config.cmpr_a = 0;/*!<Set % duty cycle for operator a(MCPWMXA), i.e for 62.3% duty cycle, duty_a = 62.3*/

pwm_config.cmpr_b = 0;/*!<Set % duty cycle for operator b(MCPWMXB), i.e for 48% duty cycle, duty_b = 48.0*/

pwm_config.counter_mode/*!<Set type of MCPWM counter*/ = MCPWM_UP_COUNTER/*!<For asymmetric MCPWM*/;

pwm_config.duty_mode/*!<Set type of duty cycle*/ = MCPWM_DUTY_MODE_0/*!<Active high duty, i.e. duty cycle proportional to high time for asymmetric MCPWM*/;

/**

* @brief Initialize MCPWM parameters

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers.

* @param mcpwm_conf configure structure mcpwm_config_t

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_0,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

}

void advance(/*范围:0~100*/uint8_t speed)

{

/**

* @brief Use this function to set MCPWM signal high

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the operator(MCPWMXA/MCPWMXB), 'x' is timer number selected

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);//给MOTOR_STEP_PIN一个持续的高电平

/**

* @brief Set duty either active high or active low(out of phase/inverted)

* @note

* Call this function every time after mcpwm_set_signal_high or mcpwm_set_signal_low to resume with previously set duty cycle

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the generator(MCPWMXA/MCPWMXB), 'x' is operator number selected

* @param duty_type set active low or active high duty type

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

/**

* @brief Set duty cycle of each operator(MCPWMXA/MCPWMXB)

*

* @param mcpwm_num set MCPWM unit(0-1)

* @param timer_num set timer number(0-2) of MCPWM, each MCPWM unit has 3 timers

* @param gen set the generator(MCPWMXA/MCPWMXB), 'X' is operator number selected

* @param duty set duty cycle in %(i.e for 62.3% duty cycle, duty = 62.3) of each operator

*

* @return

* - ESP_OK Success

* - ESP_ERR_INVALID_ARG Parameter error

*/

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//MOTOR_DIRECTION_PIN引脚输出占空比为“speed”的PWM波

}

void retreat(/*范围:0~100*/uint8_t speed)

{

//给MOTOR_STEP_PIN一个持续的低电平

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

//MOTOR_DIRECTION_PIN引脚输出占空比为“speed”的PWM波

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);

}

void breake(void)

{

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

// mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

}

void wheelSpeed()

{

int Lstate = digitalRead(encoder0pinA);

if((encoder0PinALast == LOW) && Lstate==HIGH)

{

int val = digitalRead(encoder0pinB);

if(val == LOW && Direction)

{

Direction = false; //Reverse

}

else if(val == HIGH && !Direction)

{

Direction = true; //Forward

}

}

encoder0PinALast = Lstate;

if(!Direction)

duration++;

else

duration--;

}

void EncoderInit()

{

Direction = true;//default -> Forward

pinMode(encoder0pinB,INPUT);

attachInterrupt(digitalPinToInterrupt(encoder0pinA), wheelSpeed, CHANGE);

}

void setup() {

Serial.begin(9600);//Initialize the serial port

mcpwm_init();

advance(70);

Setpoint =80; //设置PID的输出值

myPID.SetMode(AUTOMATIC);//设置PID为自动模式

myPID.SetSampleTime(100);//设置PID采样频率为100ms

EncoderInit();//Initialize the module

}

void loop() {

abs_duration=abs(duration);

result=myPID.Compute();//PID转换完成返回值为1

if(result)

{

Serial.print("Pluse: ");

Serial.println(duration);

duration = 0; //计数清零等待下次计数

}

}

6.2 PWM模式驱动电机

PWM控制模式真值表

| IN1 | IN2 | OUT1 | OUT2 | 说明 |

|---|---|---|---|---|

| 0 | 0 | Hi-Z | Hi-Z | 滑行(H 桥高阻抗) |

| 0 | 1 | L | H | 后退 (OUT2 → OUT1) |

| 1 | 0 | H | L | 前进 (OUT1 → OUT2) |

| 1 | 1 | L | L | 制动(低侧慢速衰减) |

6.2.1 驱动直流电机

/**

*@brief motorSpeeddetectionbyPWM.ino

*@ 在PWM模式下的电机驱动程序

*/

#include "driver/mcpwm.h"

#include "soc/mcpwm_struct.h"

#include "soc/mcpwm_reg.h"

//IO12->M1_IN1

//IO13->M1_IN2

#define MOTOR_PWM_IN1 12

#define MOTOR_PWM_IN2 13

//初始化需要产生PWM信号的引脚

void mcpwm_init(void)

{

//绑定需要输出PWM的引脚到PWM通道上面

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0A,MOTOR_PWM_IN1);

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0B,MOTOR_PWM_IN2);

//配置mcpwm信息

mcpwm_config_t pwm_config;

pwm_config.frequency = 1000;/*!<Set frequency of MCPWM in Hz*/

pwm_config.cmpr_a = 0;/*!<Set % duty cycle for operator a(MCPWMXA), i.e for 62.3% duty cycle, duty_a = 62.3*/

pwm_config.cmpr_b = 0;/*!<Set % duty cycle for operator b(MCPWMXB), i.e for 48% duty cycle, duty_b = 48.0*/

pwm_config.counter_mode/*!<Set type of MCPWM counter*/ = MCPWM_UP_COUNTER/*!<For asymmetric MCPWM*/;

pwm_config.duty_mode/*!<Set type of duty cycle*/ = MCPWM_DUTY_MODE_0/*!<Active high duty, i.e. duty cycle proportional to high time for asymmetric MCPWM*/;

//初始化mcpwm的某一个单元并绑定时钟

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_0,&pwm_config);

}

void advance(/*范围:0~100*/uint8_t speed)

{

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);

}

void retreat(/*范围:0~100*/uint8_t speed)

{

//给MOTOR_DIRECTION_PIN一个持续的低电平

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

/*

* Call function mcpwm_set_duty_type() every time after mcpwm_set_signal_high()

* or mcpwm_set_signal_low() to resume with previously set duty cycle.

*/

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B,MCPWM_DUTY_MODE_0);

//MOTOR_STEP_PIN引脚输出占空比为“speed”的PWM波

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B,speed);

}

void stop(void)

{

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

}

void breake(void)

{

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

}

void setup() {

mcpwm_init();

}

void loop() {

advance(30);

delay(2000);

retreat(60);

delay(2000);

stop();

delay(2000);

advance(30);

delay(2000);

retreat(60);

delay(2000);

breake();

delay(2000);

}

6.2.2 驱动带编码器直流电机

通过PID控制电机转动速度

/**

*@brief motorSpeeddetectionbyPWMwithencoder.ino

*@ 在PWM模式下的电机驱动程序(带编码器)

*/

#include "driver/mcpwm.h"

#include "soc/mcpwm_struct.h"

#include "soc/mcpwm_reg.h"

#include <PID_v1.h>

//IO12->M1_IN1

//IO13->M1_IN2

#define MOTOR_PWM_IN1 12

#define MOTOR_PWM_IN2 13

const byte encoder0pinA = 3;//A pin -> the interrupt pin 3

const byte encoder0pinB = 4;//B pin -> the digital pin 4

byte encoder0PinALast;

double duration,abs_duration;//the number of the pulses

boolean Direction;//the rotation direction

boolean result;

double val_output;//用于提供给电机PWM功率值。

double Setpoint;

double Kp=0.6, Ki=5, Kd=0;

PID myPID(&abs_duration, &val_output, &Setpoint, Kp, Ki, Kd, DIRECT);

//初始化需要产生PWM信号的引脚

void mcpwm_init(void)

{

//绑定需要输出PWM的引脚到PWM通道上面

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0A,MOTOR_PWM_IN1);

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0B,MOTOR_PWM_IN2);

//配置mcpwm信息

mcpwm_config_t pwm_config;

pwm_config.frequency = 1000;/*!<Set frequency of MCPWM in Hz*/

pwm_config.cmpr_a = 0;/*!<Set % duty cycle for operator a(MCPWMXA), i.e for 62.3% duty cycle, duty_a = 62.3*/

pwm_config.cmpr_b = 0;/*!<Set % duty cycle for operator b(MCPWMXB), i.e for 48% duty cycle, duty_b = 48.0*/

pwm_config.counter_mode/*!<Set type of MCPWM counter*/ = MCPWM_UP_COUNTER/*!<For asymmetric MCPWM*/;

pwm_config.duty_mode/*!<Set type of duty cycle*/ = MCPWM_DUTY_MODE_0/*!<Active high duty, i.e. duty cycle proportional to high time for asymmetric MCPWM*/;

//初始化mcpwm的某一个单元并绑定时钟

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_0,&pwm_config);

}

void advance(/*范围:0~100*/uint8_t speed)

{

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);

}

void retreat(/*范围:0~100*/uint8_t speed)

{

//给MOTOR_DIRECTION_PIN一个持续的低电平

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

/*

* Call function mcpwm_set_duty_type() every time after mcpwm_set_signal_high()

* or mcpwm_set_signal_low() to resume with previously set duty cycle.

*/

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B,MCPWM_DUTY_MODE_0);

//MOTOR_STEP_PIN引脚输出占空比为“speed”的PWM波

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B,speed);

}

void stop(void)

{

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

}

void breake(void)

{

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);

}

void wheelSpeed()

{

int Lstate = digitalRead(encoder0pinA);

if((encoder0PinALast == LOW) && Lstate==HIGH)

{

int val = digitalRead(encoder0pinB);

if(val == LOW && Direction)

{

Direction = false; //Reverse

}

else if(val == HIGH && !Direction)

{

Direction = true; //Forward

}

}

encoder0PinALast = Lstate;

if(!Direction)

duration++;

else

duration--;

}

void EncoderInit()

{

Direction = true;//default -> Forward

pinMode(encoder0pinB,INPUT);

attachInterrupt(digitalPinToInterrupt(encoder0pinA), wheelSpeed, CHANGE);

}

void setup() {

Serial.begin(115200);//Initialize the serial port

mcpwm_init();

advance(70);

Setpoint =80; //设置PID的输出值

myPID.SetMode(AUTOMATIC);//设置PID为自动模式

myPID.SetSampleTime(100);//设置PID采样频率为100ms

EncoderInit();//Initialize the module

}

void loop() {

abs_duration=abs(duration);

result=myPID.Compute();//PID转换完成返回值为1

if(result)

{

Serial.print("Pluse: ");

Serial.println(duration);

duration = 0; //计数清零等待下次计数

}

}

6.3 驱动小车实践

按照接线图连接硬件,烧录代码,连接"ESP32 S3 Romeo",在浏览器进入192.168.4.1即可驱动小车和查看摄像头数据

使用前请下载安装

#include "esp_camera.h"

#include <Arduino.h>

#include <WiFi.h>

#include <AsyncTCP.h>

#include <ESPAsyncWebServer.h>

#include <iostream>

#include <sstream>

#include "DFRobot_AXP313A.h"

#include "driver/mcpwm.h"

#include "soc/mcpwm_struct.h"

#include "soc/mcpwm_reg.h"

DFRobot_AXP313A axp;

#define M1_EN 12

#define M1_PN 13

#define M2_EN 14

#define M2_PN 21

#define M3_EN 9

#define M3_PN 10

#define M4_EN 47

#define M4_PN 11

#define UP 1

#define DOWN 2

#define LEFT 3

#define RIGHT 4

#define STOP 0

#define FORWARD 1

#define BACKWARD -1

//Camera related constants

#define PWDN_GPIO_NUM -1

#define RESET_GPIO_NUM -1

#define XCLK_GPIO_NUM 45

#define SIOD_GPIO_NUM 1

#define SIOC_GPIO_NUM 2

#define Y9_GPIO_NUM 48

#define Y8_GPIO_NUM 46

#define Y7_GPIO_NUM 8

#define Y6_GPIO_NUM 7

#define Y5_GPIO_NUM 4

#define Y4_GPIO_NUM 41

#define Y3_GPIO_NUM 40

#define Y2_GPIO_NUM 39

#define VSYNC_GPIO_NUM 6

#define HREF_GPIO_NUM 42

#define PCLK_GPIO_NUM 5

const char* ssid = "ESP32 S3 Romeo";

const char* password = "12345678";

AsyncWebServer server(80);

AsyncWebSocket wsCamera("/Camera");

AsyncWebSocket wsCarInput("/CarInput");

uint32_t cameraClientId = 0;

uint8_t Speed = 50;

const char* htmlHomePage PROGMEM = R"HTMLHOMEPAGE(

<!DOCTYPE html>

<html>

<head>

<meta name="viewport" content="width=device-width, initial-scale=1, maximum-scale=1, user-scalable=no">

<style>

.arrows {

font-size:30px;

color:red;

}

td.button {

background-color:black;

border-radius:25%;

box-shadow: 5px 5px #888888;

}

td.button:active {

transform: translate(5px,5px);

box-shadow: none;

}

.noselect {

-webkit-touch-callout: none; /* iOS Safari */

-webkit-user-select: none; /* Safari */

-khtml-user-select: none; /* Konqueror HTML */

-moz-user-select: none; /* Firefox */

-ms-user-select: none; /* Internet Explorer/Edge */

user-select: none; /* Non-prefixed version, currently

supported by Chrome and Opera */

}

.slidecontainer {

width: 100%;

}

.slider {

-webkit-appearance: none;

width: 100%;

height: 15px;

border-radius: 5px;

background: #d3d3d3;

outline: none;

opacity: 0.7;

-webkit-transition: .2s;

transition: opacity .2s;

}

.slider:hover {

opacity: 1;

}

.slider::-webkit-slider-thumb {

-webkit-appearance: none;

appearance: none;

width: 25px;

height: 25px;

border-radius: 50%;

background: red;

cursor: pointer;

}

.slider::-moz-range-thumb {

width: 25px;

height: 25px;

border-radius: 50%;

background: red;

cursor: pointer;

}

</style>

</head>

<body class="noselect" align="center" style="background-color:white">

<table id="mainTable" style="width:400px;margin:auto;table-layout:fixed" CELLSPACING=10>

<tr>

<img id="cameraImage" src="" style="width:400px;height:250px"></td>

</tr>

<tr>

<td></td>

<td class="button" ontouchstart='sendButtonInput("MoveCar","1")' ontouchend='sendButtonInput("MoveCar","0")'><span class="arrows" >⇧</span></td>

<td></td>

</tr>

<tr>

<td class="button" ontouchstart='sendButtonInput("MoveCar","3")' ontouchend='sendButtonInput("MoveCar","0")'><span class="arrows" >⇦</span></td>

<td class="button"></td>

<td class="button" ontouchstart='sendButtonInput("MoveCar","4")' ontouchend='sendButtonInput("MoveCar","0")'><span class="arrows" >⇨</span></td>

</tr>

<tr>

<td></td>

<td class="button" ontouchstart='sendButtonInput("MoveCar","2")' ontouchend='sendButtonInput("MoveCar","0")'><span class="arrows" >⇩</span></td>

<td></td>

</tr>

<tr/><tr/>

<tr>

<td style="text-align:left"><b>Speed:</b></td>

<td colspan=2>

<div class="slidecontainer">

<input type="range" min="0" max="100" value="50" class="slider" id="Speed" oninput='sendButtonInput("Speed",value)'>

</div>

</td>

</tr>

</table>

<script>

var webSocketCameraUrl = "ws:\/\/" + window.location.hostname + "/Camera";

var webSocketCarInputUrl = "ws:\/\/" + window.location.hostname + "/CarInput";

var websocketCamera;

var websocketCarInput;

function initCameraWebSocket()

{

websocketCamera = new WebSocket(webSocketCameraUrl);

websocketCamera.binaryType = 'blob';

websocketCamera.onopen = function(event){};

websocketCamera.onclose = function(event){setTimeout(initCameraWebSocket, 2000);};

websocketCamera.onmessage = function(event)

{

var imageId = document.getElementById("cameraImage");

imageId.src = URL.createObjectURL(event.data);

};

}

function initCarInputWebSocket()

{

websocketCarInput = new WebSocket(webSocketCarInputUrl);

websocketCarInput.onopen = function(event)

{

sendButtonInput("Speed", document.getElementById("Speed").value);

};

websocketCarInput.onclose = function(event){setTimeout(initCarInputWebSocket, 2000);};

websocketCarInput.onmessage = function(event){};

}

function initWebSocket()

{

initCameraWebSocket ();

initCarInputWebSocket();

}

function sendButtonInput(key, value)

{

var data = key + "," + value;

websocketCarInput.send(data);

}

window.onload = initWebSocket;

document.getElementById("mainTable").addEventListener("touchend", function(event){

event.preventDefault()

});

</script>

</body>

</html>

)HTMLHOMEPAGE";

void advance(uint8_t motorNumber,uint8_t speed)

{

switch(motorNumber)

{

case 1:

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);//给PH一个持续的高电平

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 2:

mcpwm_set_signal_high(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_B);//给PH一个持续的高电平

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 3:

mcpwm_set_signal_high(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_B);//给PH一个持续的高电平

mcpwm_set_duty_type(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 4:

mcpwm_set_signal_high(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_B);//给PH一个持续的高电平

mcpwm_set_duty_type(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

}

}

void retreat(uint8_t motorNumber,uint8_t speed)

{

switch(motorNumber)

{

case 1:

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_B);//给PH一个持续的低电平

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 2:

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_B);//给PH一个持续的低电平

mcpwm_set_duty_type(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 3:

mcpwm_set_signal_low(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_B);//给PH一个持续的低电平

mcpwm_set_duty_type(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

case 4:

mcpwm_set_signal_low(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_B);//给PH一个持续的低电平

mcpwm_set_duty_type(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_A,MCPWM_DUTY_MODE_0);

mcpwm_set_duty(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_A,speed);//EN引脚输出占空比为“speed”的PWM波

break;

}

}

void breake(uint8_t motorNumber)

{

switch(motorNumber)

{

case 1:

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_0,MCPWM_GEN_A);

break;

case 2:

mcpwm_set_signal_low(MCPWM_UNIT_0,MCPWM_TIMER_1,MCPWM_GEN_A);

break;

case 3:

mcpwm_set_signal_low(MCPWM_UNIT_1,MCPWM_TIMER_0,MCPWM_GEN_A);

break;

case 4:

mcpwm_set_signal_low(MCPWM_UNIT_1,MCPWM_TIMER_1,MCPWM_GEN_A);

break;

}

}

void moveCar(uint8_t inputValue,uint8_t speed)

{

switch(inputValue)

{

case UP:

advance(1,speed);

advance(2,speed);

advance(3,speed);

advance(4,speed);

break;

case DOWN:

retreat(1,speed);

retreat(2,speed);

retreat(3,speed);

retreat(4,speed);

break;

case LEFT:

advance(2,speed);

advance(4,speed);

retreat(1,speed);

retreat(3,speed);

break;

case RIGHT:

advance(1,speed);

advance(3,speed);

retreat(2,speed);

retreat(4,speed);

break;

case STOP:

breake(1);

breake(2);

breake(3);

breake(4);

break;

}

}

void handleRoot(AsyncWebServerRequest *request)

{

request->send_P(200, "text/html", htmlHomePage);

}

void handleNotFound(AsyncWebServerRequest *request)

{

request->send(404, "text/plain", "File Not Found");

}

void onCarInputWebSocketEvent(AsyncWebSocket *server,

AsyncWebSocketClient *client,

AwsEventType type,

void *arg,

uint8_t *data,

size_t len)

{

switch (type)

{

case WS_EVT_CONNECT:

Serial.printf("WebSocket client #%u connected from %s\n", client->id(), client->remoteIP().toString().c_str());

break;

case WS_EVT_DISCONNECT:

Serial.printf("WebSocket client #%u disconnected\n", client->id());

moveCar(STOP,0);

//ledcWrite(PWMLightChannel, 0);

//panServo.write(90);

//tiltServo.write(90);

break;

case WS_EVT_DATA:

AwsFrameInfo *info;

info = (AwsFrameInfo*)arg;

if (info->final && info->index == 0 && info->len == len && info->opcode == WS_TEXT)

{

std::string myData = "";

myData.assign((char *)data, len);

std::istringstream ss(myData);

std::string key, value;

std::getline(ss, key, ',');

std::getline(ss, value, ',');

Serial.printf("Key [%s] Value[%s]\n", key.c_str(), value.c_str());

int valueInt = atoi(value.c_str());

if (key == "MoveCar")

{

moveCar(valueInt,Speed);

}

else if (key == "Speed")

{

Speed = valueInt;

}

/*else if (key == "Light")

{

//ledcWrite(PWMLightChannel, valueInt);

}

else if (key == "Pan")

{

//panServo.write(valueInt);

}

else if (key == "Tilt")

{

//tiltServo.write(valueInt);

} */

}

break;

case WS_EVT_PONG:

case WS_EVT_ERROR:

break;

default:

break;

}

}

void onCameraWebSocketEvent(AsyncWebSocket *server,

AsyncWebSocketClient *client,

AwsEventType type,

void *arg,

uint8_t *data,

size_t len)

{

switch (type)

{

case WS_EVT_CONNECT:

Serial.printf("WebSocket client #%u connected from %s\n", client->id(), client->remoteIP().toString().c_str());

cameraClientId = client->id();

break;

case WS_EVT_DISCONNECT:

Serial.printf("WebSocket client #%u disconnected\n", client->id());

cameraClientId = 0;

break;

case WS_EVT_DATA:

break;

case WS_EVT_PONG:

case WS_EVT_ERROR:

break;

default:

break;

}

}

void setupCamera()

{

camera_config_t config;

config.ledc_channel = LEDC_CHANNEL_0;

config.ledc_timer = LEDC_TIMER_0;

config.pin_d0 = Y2_GPIO_NUM;

config.pin_d1 = Y3_GPIO_NUM;

config.pin_d2 = Y4_GPIO_NUM;

config.pin_d3 = Y5_GPIO_NUM;

config.pin_d4 = Y6_GPIO_NUM;

config.pin_d5 = Y7_GPIO_NUM;

config.pin_d6 = Y8_GPIO_NUM;

config.pin_d7 = Y9_GPIO_NUM;

config.pin_xclk = XCLK_GPIO_NUM;

config.pin_pclk = PCLK_GPIO_NUM;

config.pin_vsync = VSYNC_GPIO_NUM;

config.pin_href = HREF_GPIO_NUM;

config.pin_sscb_sda = SIOD_GPIO_NUM;

config.pin_sscb_scl = SIOC_GPIO_NUM;

config.pin_pwdn = PWDN_GPIO_NUM;

config.pin_reset = RESET_GPIO_NUM;

config.xclk_freq_hz = 20000000;

config.frame_size = FRAMESIZE_UXGA;

config.pixel_format = PIXFORMAT_JPEG; // for streaming

//config.pixel_format = PIXFORMAT_RGB565; // for face detection/recognition

config.grab_mode = CAMERA_GRAB_WHEN_EMPTY;

config.fb_location = CAMERA_FB_IN_PSRAM;

config.jpeg_quality = 12;

config.fb_count = 1;

// if PSRAM IC present, init with UXGA resolution and higher JPEG quality

// for larger pre-allocated frame buffer.

if(config.pixel_format == PIXFORMAT_JPEG){

if(psramFound()){

config.jpeg_quality = 10;

config.fb_count = 2;

config.grab_mode = CAMERA_GRAB_LATEST;

} else {

// Limit the frame size when PSRAM is not available

config.frame_size = FRAMESIZE_SVGA;

config.fb_location = CAMERA_FB_IN_DRAM;

}

} else {

// Best option for face detection/recognition

config.frame_size = FRAMESIZE_240X240;

#if CONFIG_IDF_TARGET_ESP32S3

config.fb_count = 2;

#endif

}

// camera init

esp_err_t err = esp_camera_init(&config);

if (err != ESP_OK)

{

Serial.printf("Camera init failed with error 0x%x", err);

return;

}

if (psramFound())

{

heap_caps_malloc_extmem_enable(20000);

Serial.printf("PSRAM initialized. malloc to take memory from psram above this size");

}

}

void sendCameraPicture()

{

if (cameraClientId == 0)

{

return;

}

unsigned long startTime1 = millis();

//capture a frame

camera_fb_t * fb = esp_camera_fb_get();

if (!fb)

{

Serial.println("Frame buffer could not be acquired");

return;

}

unsigned long startTime2 = millis();

wsCamera.binary(cameraClientId, fb->buf, fb->len);

esp_camera_fb_return(fb);

//Wait for message to be delivered

while (true)

{

AsyncWebSocketClient * clientPointer = wsCamera.client(cameraClientId);

if (!clientPointer || !(clientPointer->queueIsFull()))

{

break;

}

delay(1);

}

unsigned long startTime3 = millis();

Serial.printf("Time taken Total: %d|%d|%d\n",startTime3 - startTime1, startTime2 - startTime1, startTime3-startTime2 );

}

//初始化需要产生PWM信号的引脚

void mcpwm_init(void)

{

//配置mcpwm信息

mcpwm_config_t pwm_config;

pwm_config.frequency = 1000;

pwm_config.cmpr_a = 0;

pwm_config.cmpr_b = 0;

pwm_config.counter_mode = MCPWM_UP_COUNTER;

pwm_config.duty_mode = MCPWM_DUTY_MODE_0;

//A速度 B方向

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0A,M1_EN);//电机1 GPIO

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM0B,M1_PN);

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_0,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM1A,M2_EN);//电机2 GPIO

mcpwm_gpio_init(MCPWM_UNIT_0,MCPWM1B,M2_PN);

mcpwm_init(MCPWM_UNIT_0,MCPWM_TIMER_1,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

mcpwm_gpio_init(MCPWM_UNIT_1,MCPWM0A,M3_EN);//电机3 GPIO

mcpwm_gpio_init(MCPWM_UNIT_1,MCPWM0B,M3_PN);

mcpwm_init(MCPWM_UNIT_1,MCPWM_TIMER_0,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

mcpwm_gpio_init(MCPWM_UNIT_1,MCPWM1A,M4_EN);//电机4 GPIO

mcpwm_gpio_init(MCPWM_UNIT_1,MCPWM1B,M4_PN);

mcpwm_init(MCPWM_UNIT_1,MCPWM_TIMER_1,&pwm_config);//初始化mcpwm的某一个单元并绑定时钟

}

void setup(void)

{

Serial.begin(115200);

while(axp.begin() != 0){

Serial.println("init error");

delay(1000);

}

axp.enableCameraPower(axp.eOV2640);//设置摄像头供电

mcpwm_init();

WiFi.softAP(ssid, password);

IPAddress IP = WiFi.softAPIP();

Serial.print("AP IP address: ");

Serial.println(IP);

server.on("/", HTTP_GET, handleRoot);

server.onNotFound(handleNotFound);

wsCamera.onEvent(onCameraWebSocketEvent);

server.addHandler(&wsCamera);

wsCarInput.onEvent(onCarInputWebSocketEvent);

server.addHandler(&wsCarInput);

server.begin();

Serial.println("HTTP server started");

setupCamera();

}

void loop()

{

wsCamera.cleanupClients();

wsCarInput.cleanupClients();

sendCameraPicture();

//Serial.printf("SPIRam Total heap %d, SPIRam Free Heap %d\n", ESP.getPsramSize(), ESP.getFreePsram());

}

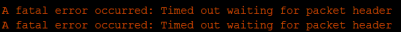

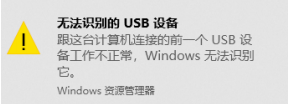

常见问题

原因

-

如果Loop中延时过短或者不加延时会导致烧录超时

-

错误的调用一些函数会导致计算机不能识别USB

解决办法

- 按住BOOT,再按下RST,然后松开两个按键,再烧录。

串口无打印

解决办法

- 检查USB CDC是否处于Enable状态

- 使用其他的串口调试助手查看打印信息

更多问题及有趣的应用,可以 访问论坛 进行查阅或发帖。