简介

该传感器是一款适合防抖应用的高精度六轴IMU模块,包含3轴加速度(±2/4/8/16g)和3轴陀螺仪(±125/250/500dps),具有16位ADC采样,初始灵敏度均高达±1%,且噪声较低(6.5mdps /√Hz)。此外该传感器还包含一个512字节大的FIFO,可减少串行总线接口上的流量。有可编程中断、帧同步等功能。其中,帧同步功能可以联动其他图像/视频采集设备一起使用,十分适合用于OIS(光学稳定成像)/EIS(电子稳定成像系统)项目中。

特性

- 六轴IMU(3轴加速度+3轴陀螺仪)

- 高性能:高初始灵敏度(均为1%);高精度(16bit ADC);噪声较低(6.5mdps/√Hz)

- 512字节的FIFO

- 功能丰富:外部可编程中断、帧同步、睡眠唤醒、运动检测

应用场景

- 手机相机模块

- 数码单反相机中的图像稳定

- 运动手表

技术规格

- 工作电压:3.3V

- 三轴加速度模式电流消耗:0.52mA

- 三轴陀螺仪模式电流消耗:4.27mA

- 三轴加速度和三轴陀螺仪电流消耗:4.9mA

- 睡眠模式电流消耗:0.14mA

- 集成16位ADC

- 初始灵敏度:加速度±1%,陀螺仪±1%

- 非线性灵敏度:加速度±0.5%,陀螺仪±0.1%

- 接口方式:I2C/SPI(7MHz)

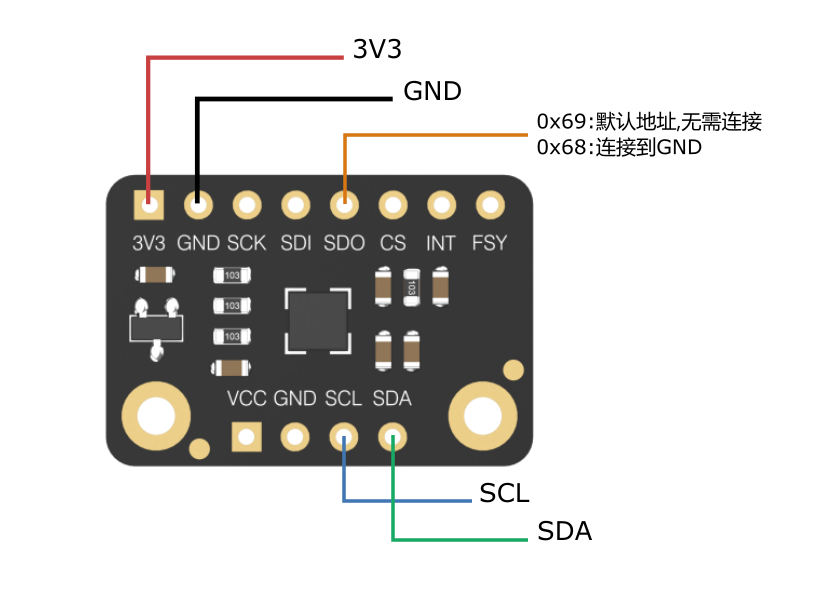

- I2C地址:0x69(默认)/0x68

- 低噪声:6.5mdps /√Hz

- 可选量程:±2g/±4g/±8g/±16g

- 陀螺仪范围:±125/±250/±500 dps

- 数据输出频率:1000~8000 Hz

- 陀螺仪启动时间:80 ms

- 加速度计的启动时间:20ms(从睡眠唤醒)/30ms(初次启动)

- 工作温度范围:-40~+85℃

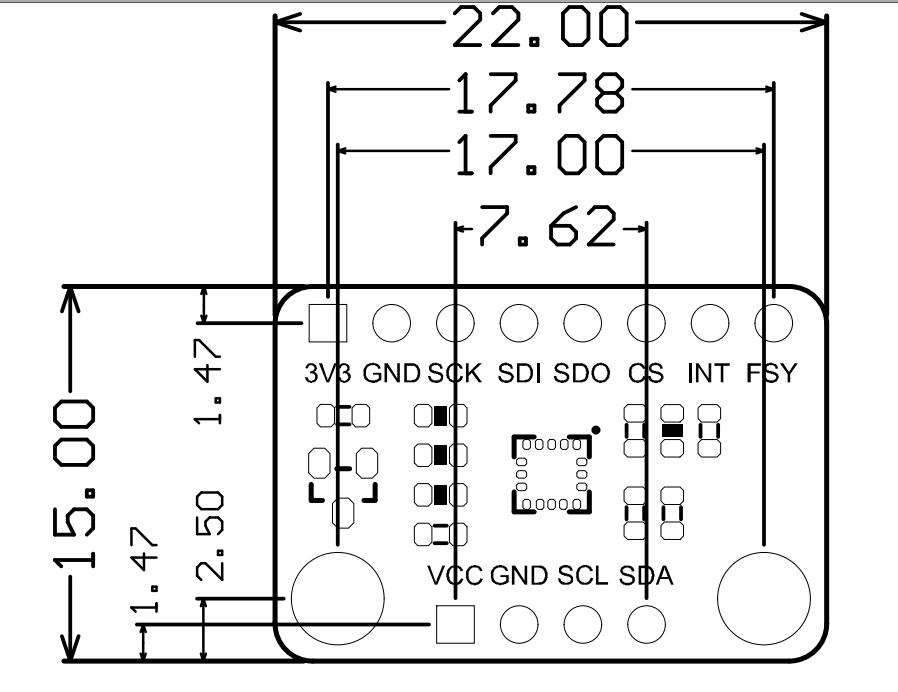

- 模块尺寸:15x22mm

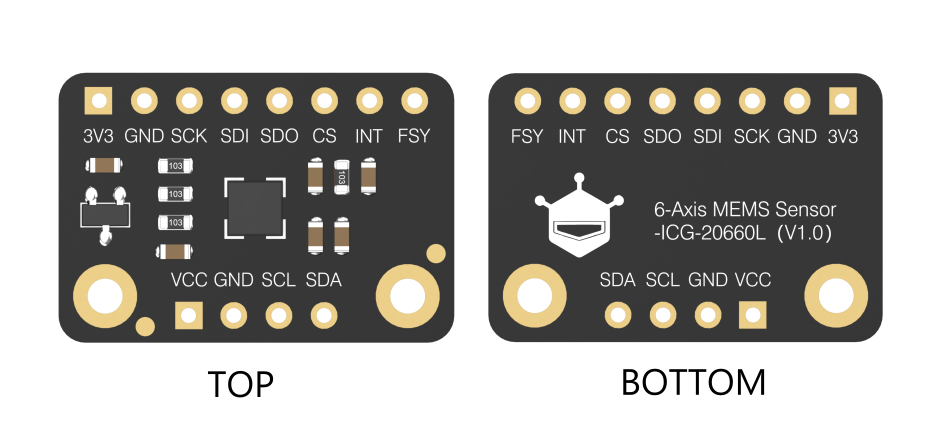

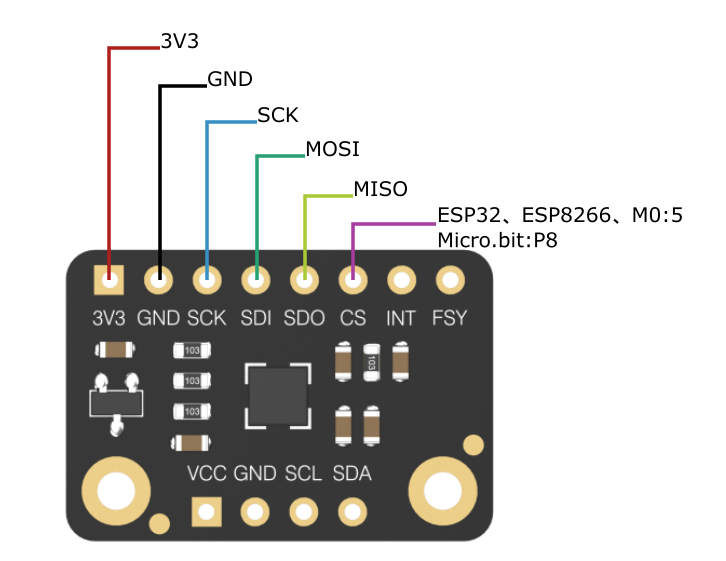

引脚说明

| 序号 | 丝印 | 功能描述 |

|---|---|---|

| 1 | VCC | 3.3V~5V电源输入 |

| 2 | 3V3 | 3.3V电源输入/输出 |

| 3 | GND | GND |

| 4 | SCL | I2C时钟线 |

| 5 | SDA | I2C数据线 |

| 6 | SCK | SPI时钟控制线 |

| 7 | SDI | SPI数据线(输入) |

| 8 | SDO | I2C 地址选择引脚/SPI 数据线(输出) |

| 9 | CS | SPI 片选线 |

| 10 | INT | 中断引脚 |

| 11 | FSY | 同步数字输入(可选) |

*FSY引脚功能:高级用户可将该引脚与其他传感器(例如图像采集模块)结合起来使用以实现整个项目的更好联动,具体的用法请查阅芯片手册

注意:

- 仅支持3.3V主板

- 所有数据输出电压均为3.3V

- I2C连接5V输入会影响传感器的寿命

不同通信方式连线提示:

- I2C:0x69(默认)/ 0x68

- SPI

- demo中的中断引脚连接

| 主板 | 默认连接引脚 |

|---|---|

| Micro:bit | P9 |

| ESP32 | D9 |

| ESP8266 | D5 |

| Raspberry Pi | BCM27 |

- 中断引脚在使用时才进行连接

M0使用教程

准备

- 硬件

- 1 x Firebeetle Board-M0

- 1 x 六轴IMU传感器

- 若干 杜邦线

- 软件

- Arduino IDE, 点击下载Arduino IDE

- 库文件和示例程序

关于如何安装库文件,点击链接

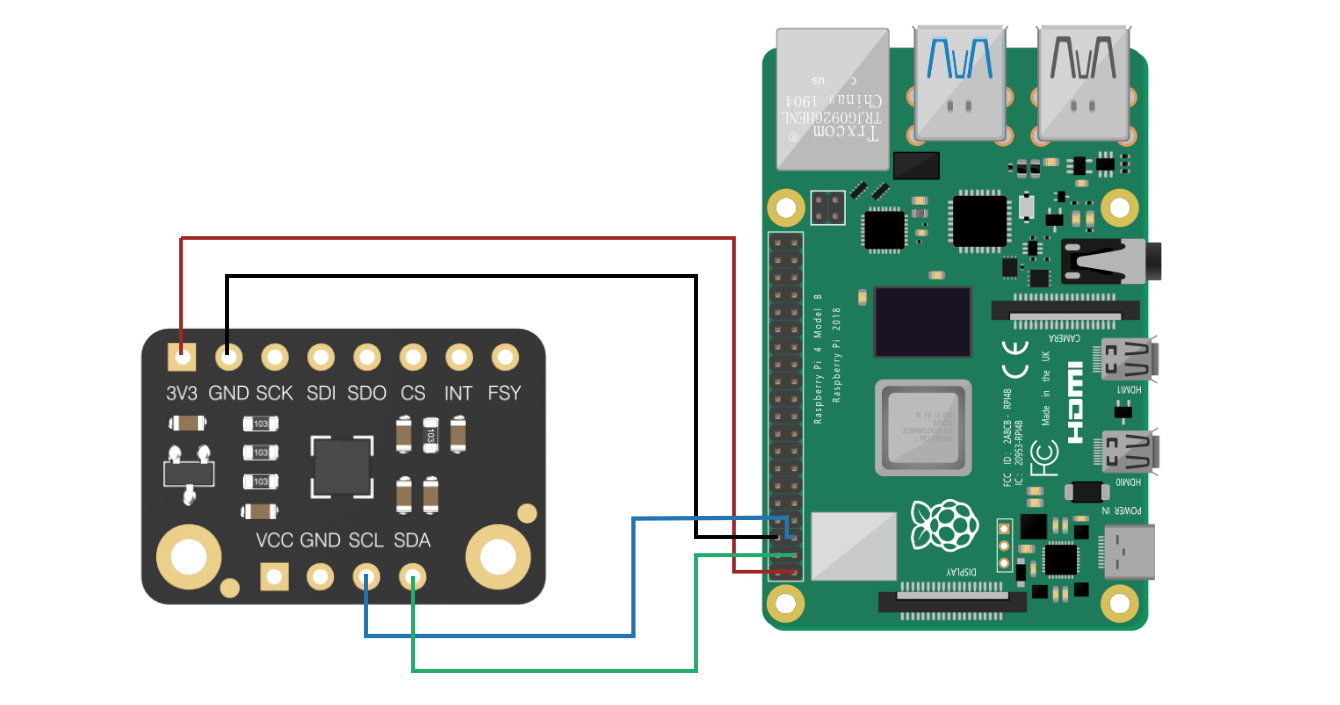

接线图

请按接线图所示将传感器与M0(或其它主板)相连接即可。

-

样例代码

- 主要API接口函数列表

/**

* @brief The constructor of the ICG20660L sensor, using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC(uint8_t addr = IIC_ADDR_SDO_H, TwoWire *pWire = &Wire);

/**

* @brief The constructor of the ICG20660L sensor, using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

DFRobot_ICG20660L_SPI(int csPin, SPIClass *spi);

/**

* @brief Initialize the sensor, after initialization, all sensors are turned off, and the corresponding configuration

* @n needs to be turned on through enableSensor.

* @param mode: Enum variable,from eDataReadMode_t, configure to read sensor data from FIFO or register?

* @n eRegMode: Read sensor data from registers.

* @n eFIFOMode:Read sensor data from 512 bytes FIFO. Note: Read from FIFO, accelerometer, gyroscope and temperature must all be enabled,

* @n and the internal sampling rate must be configured to be consistent.

* @return status:

* @n 0 : Initialization success.

* @n -1: Interface initialization failed(IIC or SPI).

* @n -2: Failed to read the device ID, the ID is not 0x91

*/

int begin(eDataReadMode_t mode = eRegMode);

/**

* @brief Get device ID, ICG20660L is 0x91 (145).

* @return If device is ICG20660L, it will return 0x91.

*/

uint8_t readID();

/**

* @brief Enable sensor, including Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8-bit byte data. Each bit represents enabling a function bit, as shown in the following table:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: Enabling any axis of the gyroscope will automatically enable the on-board temperature sensor.

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit,

* @n enable temperature, Accel's and gyro's xyz axis.

*/

void enableSensor(uint8_t bit);

/**

* @brief Disable sensor, including Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8-bit byte data. Each bit represents enabling a function bit, as shown in the following table:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: Only when the X, Y, and Z axes of the gyroscope are all closed, the temperature sensor will be turned off.

* @n Any axis’s turning on will make the temperature sensor not be turned off.

* @n eGyroAxisZ: The bit0 of the bit, disable gyro's z axis.

* @n eGyroAxisY: The bit1 of the bit, disable gyro's y axis.

* @n eGyroAxisX: The bit2 of the bit, disable gyro's X axis.

* @n eAccelAxisZ: The bit3 of the bit, disable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, disable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, disable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, disable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, disable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit,

* @n disable temperature, Accel's and gyro's xyz axis.

*/

void disableSensor(uint8_t bit);

/**

* @brief Config of gyro's full scale, dlpf bandwidth and internal sample rate.

* @param scale The full scale of gyro, unit: dps(Degrees per second).

* @n eFSR_G_125DPS: The full scale range is ±125 dps.

* @n eFSR_G_250DPS: The full scale range is ±250 dps.

* @n eFSR_G_500DPS: The full scale range is ±500 dps.

* @param bd Set 3-db bandwidth.

* @n eGyro_DLPF_8173_32KHZ: When the signal is equal to or greater than 8173Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 32KHz.

* @n eGyro_DLPF_3281_32KHZ: When the signal is equal to or greater than 3281Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 32KHz.

* @n eGyro_DLPF_250_8KHZ: When the signal is equal to or greater than 250Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 8KHz.

* @n eGyro_DLPF_176_1KHZ: When the signal is equal to or greater than 176Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eGyro_DLPF_92_1KHZ: When the signal is equal to or greater than 92Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eGyro_DLPF_3281_8KHZ: When the signal is equal to or greater than 3281Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 8KHz.

* @n Note: When the gyroscope and accelerometer are both enabled, if the sensor data is read through the FIFO,

* @n the internal sampling rate of the gyroscope and accelerometer must be the same.

*/

void configGyro(eGyroFSR_t scale, eGyroBandwidth_t bd);

void configGyro(uint8_t scale, uint8_t bd);

/**

* @brief Config of accel's full scale, dlpf bandwidth and internal sample rate.

* @param scale The full scale of accel, unit: g(1g = 9.80665 m/s²).

* @n eFSR_A_2G: The full scale range is ±2g.

* @n eFSR_A_4G: The full scale range is ±4g.

* @n eFSR_A_8G: The full scale range is ±8g.

* @n eFSR_A_16G: The full scale range is ±16g.

* @param bd Set 3-db bandwidth.

* @n eAccel_DLPF_5_1KHZ or 0: When the signal is less than or equal to 5Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eAccel_DLPF_10_1KHZ or 1: When the signal is less than or equal to 10Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eAccel_DLPF_21_1KHZ or 2: When the signal is less than or equal to 21Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eAccel_DLPF_44_1KHZ or 3: When the signal is less than or equal to 44Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eAccel_DLPF_99_1KHZ or 4: When the signal is less than or equal to 99Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz.

* @n eAccel_DLPF_218_1KHZ or 5: When the signal is less than or equal to 218Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz. Support low power consumption mode

* @n eAccel_DLPF_420_1KHZ or 6: When the signal is less than or equal to 420Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz. Support low power consumption mode

* @n eAccel_DLPF_1046_4KHZ or 7: When the signal is less than or equal to 1046Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 4KHz. Support low power consumption mode

* @n eAccel_DLPF_55_1KHZ or 8: When the signal is less than or equal to 55Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz. Only support low power consumption mode

* @n eAccel_DLPF_110_1KHZ or 9: When the signal is less than or equal to 110Hz, there will be obvious attenuation, 3-db attenuation, and the internal sampling rate is 1KHz. Only support low power consumption mode

* @n Note: When the gyroscope and accelerometer are both enabled, if the sensor data is read through the FIFO,

* @n the internal sampling rate of the gyroscope and accelerometer must be the same.

* @param odr: Set the frequency of waking up the chip to take a sample of accel data – the low power accel Output Data Rate.

* @n eODR_125Hz or 9: The low power accel Output Data Rate: 125Hz

* @n eODR_250Hz or 10: The low power accel Output Data Rate: 250Hz

* @n eODR_500Hz or 11: The low power accel Output Data Rate: 500Hz

* @param lowPowerFlag: Whether to configure the Acceleration to low power mode.

* @n true: Enter low power mode.

* @n false: Not configure the Acceleration to low power mode.(default)

*/

void configAccel(eAccelFSR_t scale, eAccelBandwidth_t bd, eODR_t odr = eODR_0_24Hz, bool lowPowerFlag = false);

void configAccel(uint8_t scale, uint8_t bd, uint8_t odr = 0, bool lowPowerFlag = false);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n Sampling rate = internal sampling rate/(div+1)

* @n Note: If the accelerometer configuration is in low power consumption mode, that is, the formal parameter lowPowerFlag of the configAccel function is true,

* @n the sampling rate must match the output rate of the formal parameter odr of configAccel, as shown in the following table:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n |bd of supporting low power consumption mode| eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

void setSampleDiv(uint8_t div);

/**

* @brief Reset, the register will restore the initial value, and you need to call begin to configuration.

*/

void reset();

/**

* @brief Entering sleep mode, it will reduce power consumption, and The gyroscope and acceleration will stop working.

* @n You need to call wakeup function to wake up sensor.

*/

void sleep();

/**

* @brief Wake up sensor from sleep, and you will restore the configuration before sleep.

*/

void wakeup();

/**

* @brief Set the level polarity of the INT pin when the accelerometer sensor is triggered to wake up the motion interrupt.

* @param polarity: the level signal of the sensor INT pin when the wake-up motion is triggered

* @n HIGH:The initial signal of the pin is LOW. When an accelerometer wake-up motion occurs, the level signal of the INT pin will change to HIGH.

* @n Then the readINTStatus function needs to be called to clear the signal and restore the initial signal.

* @n LOW: The initial signal of the pin is HIGH. When an accelerometer wake-up motion occurs, the level signal of the INT pin will change to LOW.

* @n Then the readINTStatus function needs to be called to clear the signal and restore the initial signal.

* @n Note: After triggering the accelerometer wake-up motion, if the read_int_status function is not called to clear the sign,

* @n the INT pin will always maintain the level polarity when the motion is triggered.

*/

void setINTPinMotionTriggerPolarity(int polarity);

/**

* @brief Get the polarity of the INT pin of sensor when the sensor INT pin triggers an interrupt.

* @return The level signal when the INT pin triggers an interrupt.

* @n HIGH: INT pin level held HIGH LEVEL until interrupt status is cleared.

* @n LOW: INT pin level held LOW LEVEL until interrupt status is cleared.

*/

int getINTPinMotionTriggerPolarity();

/**

* @brief Set the threshold value for the Wake on Motion Interrupt for accelerometer.

* @param level: WoM thresholds are expressed in fixed “mg” independent of the selected Range [0g : 1g]; Resolution 1g/256=~3.9mg

* @n level = 0~255

* @return Actul WoM thresholds, unit : g re_value = (level * 3.9)/1000 g

*/

float setWakeOnMotionThresholdForAccel(uint8_t level);

/**

* @brief Read interrupt status register, and clear INT pin's interrupt signal.

* @return Interrupt status register value.

* @n INT_STATUS register:addr:0x3A,acess:rw

* @n ------------------------------------------------------------------------------------

* @n | b7 | b6 | b5 | b4 | b3 | b2 | b1 | b0 |

* @n ------------------------------------------------------------------------------------

* @n | WOM_XYZ_INT | FIFO_OFLOW_INT | rsv | DATA_RDY_INT |

* @n ------------------------------------------------------------------------------------

* @n DATA_RDY_INT : This bit automatically sets to 1 when a Data Ready interrupt is generated. The bit clears to 0 after the register has been read.

* @n rsv : reserve

* @n FIFO_OFLOW_INT: This bit automatically sets to 1 when a FIFO buffer overflow has been generated. The bit clears to 0 after the register has been read.

* @n WOM_XYZ_INT : These bits automatically set to a non-zero number when the X-axis,Y-axis or Z-axis of accelerometer which trigger WOM(wake on motion)

* @n interrupt.Cleared on Read.

*/

uint8_t readINTStatus();

/**

* @brief Get Sensor's accel, gyro and temperature data.

* @param accel: sIcg20660SensorData_t structure pointer which points to accel or NULL.

* @param gyro: sIcg20660SensorData_t structure pointer which points to gyro or NULL.

* @param t: A float pointer which points to temperature or NULL.

*/

void getSensorData(sIcg20660SensorData_t *accel, sIcg20660SensorData_t *gyro, float *t);

/**

* @brief Get X axis acceleration, unit g.

* @return X axis acceleration.

*/

float getAccelDataX();

/**

* @brief Get Y axis acceleration, unit g.

* @return Y axis acceleration.

*/

float getAccelDataY();

/**

* @brief Get Z axis acceleration, unit g.

* @return Z axis acceleration.

*/

float getAccelDataZ();

/**

* @brief Get temperature data, uint: ℃.

* @return Temperature data.

*/

float getTemperatureC();

/**

* @brief Get X-axis gyroscope speed, unit dps.

* @return X-axis gyroscope speed.

*/

float getGyroDataX();

/**

* @brief Get Y-axis gyroscope speed, unit dps.

* @return Y-axis gyroscope speed.

*/

float getGyroDataY();

/**

* @brief Get Z-axis gyroscope speed, unit dps.

* @return Z-axis gyroscope speed.

*/

float getGyroDataZ();

/**

* @brief Get 14 bytes raw data, including accel, gyro and temperature.

* @param data: buffer for storing 14 bytes of raw data.

* @n The first byte of data : Acceleration X-axis high byte data.

* @n The second byte of data: Acceleration X-axis low byte data.

* @n The third byte of data : Acceleration Y-axis high byte data.

* @n The 4th byte of data : Acceleration Y-axis low byte data.

* @n The 5th byte of data : Acceleration Z-axis high byte data.

* @n The 6th byte of data : Acceleration Z-axis low byte data.

* @n The 7th byte of data : Temperature high byte data.

* @n The 8th byte of data : Temperature low byte data.

* @n The 9th byte of data : Gyro X-axis high byte data.

* @n The 10th byte of data : Gyro X-axis low byte data.

* @n The 11th byte of data : Gyro Y-axis high byte data.

* @n The 12th byte of data : Gyro Y-axis low byte data.

* @n The 13th byte of data : Gyro Z-axis high byte data.

* @n The 14th byte of data : Gyro Z-axis low byte data.

* @n Note: You can use RAW_DATA_LENGTH to creat data Arrya, and you can use

* @n RAW_DATA_AX_H_INDEX, RAW_DATA_AX_L_INDEX, RAW_DATA_AY_H_INDEX, RAW_DATA_AY_L_INDEX, RAW_DATA_AZ_H_INDEX, RAW_DATA_AZ_L_INDEX,

* @n RAW_DATA_T_H_INDEX, RAW_DATA_T_L_INDEX,RAW_DATA_GX_H_INDEX, RAW_DATA_GX_L_INDEX,

* @n RAW_DATA_GY_H_INDEX, RAW_DATA_GY_L_INDEX, RAW_DATA_GZ_H_INDEX, RAW_DATA_GZ_L_INDEX or 0~13 to index data array.

* @param len: The length of data array.

*/

void getRawData(uint8_t *data, uint8_t len = 0);

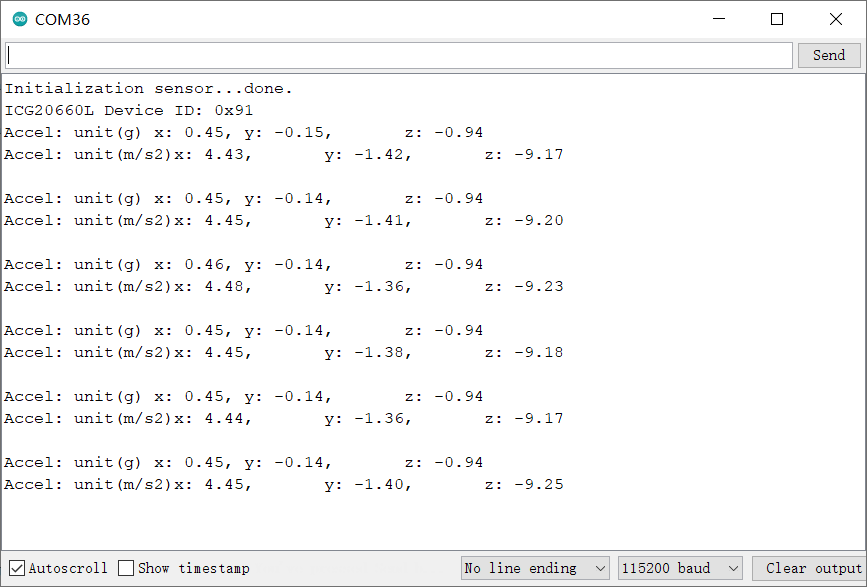

样例代码1-读取x,y,z轴加速度数据(getAccelData.ino)

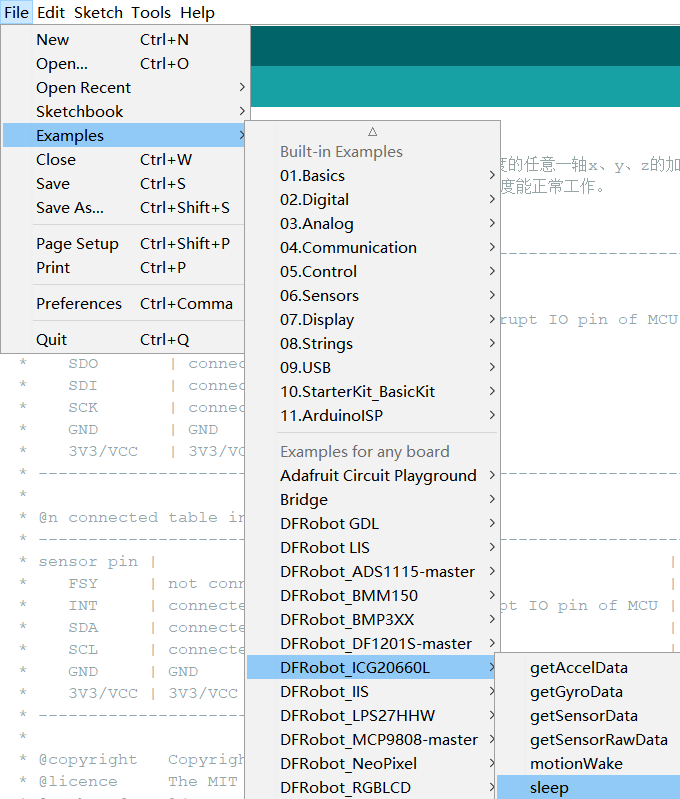

- 选择getAccelData.ino

- 烧录程序

/*!

* @file getAccelData.ino

* @brief 获取传感器的加速度数据,仅适用于寄存器模式(此demo不支持FIFO读取模式)。

*

* @n connected table in SPI

* -----------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MISO | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MOSI | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -----------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* ---------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* SDA | connected to SDA of mcu'iic | 21/SDA| SDA | SDA | P20/SDA | 20/SDA |

* SCL | connected to scl of mcu'iic | 22/SCL| SCL | SCL | P19/SCL | 21/SCL |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* ---------------------------------------------------------------------------------------------------

*

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @licence The MIT License (MIT)

* @author [Arya](xue.peng@dfrobot.com)

* @version V1.0

* @data 2021-05-24

* @get from https://www.dfrobot.com

* @url https://github.com/DFRobot/DFRobot_ICG20660L

*/

#include "DFRobot_ICG20660L.h"

#ifdef ARDUINO_BBC_MICROBIT

#define CS_PIN 8 //The CS pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#else

#define CS_PIN 5 //The CS pin of sensor which is connected to the 5 digital io pin of MCU,and also can connected to other pin.

#endif

/**

* @brief The constructor of the ICG20660L sensor using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC icg(/*addr=*/IIC_ADDR_SDO_H, &Wire);

/**

* @brief The constructor of the ICG20660L sensor using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

//DFRobot_ICG20660L_SPI icg(/*csPin=*/CS_PIN, &SPI);

float G = 9.80665; //unit: 1G = 9.80665m/s²

void setup() {

Serial.begin(115200);

while(!Serial){ //Waiting for USB Serial COM port to open.

}

Serial.print("Initialization sensor...");

/**

* @brief 初始化传感器,初始化后,所有传感器都被关闭,需通过enableSensor打开相应的配置.

* @param mode: Enum variable,from eDataReadMode_t,配置读取传感器数据是从FIFO还是从寄存器。

* @n eRegMode: 配置为从寄存器读取传感器数据

* @n eFIFOMode: 从512字节FIFO读取数据,注意:从FIFO读取,加速度,陀螺仪、温度必须全部使能,且将其内部采样率必须配置成一致。(此demo不支持)

* @return status:

* @n 0 : Initialization sucess.

* @n -1: Interface Initialization failed(IIC or SPI).

* @n -2: 读取设备ID失败,ID不是0x91

*/

while(icg.begin(/*mode=*/icg.eRegMode) != 0){

Serial.println("failed. Please check whether the hardware connection is wrong.");

delay(1000);

Serial.print("Initialization sensor...");

}

Serial.println("done.");

Serial.print("ICG20660L Device ID: 0x");

Serial.println(icg.readID(), HEX);

/**

* @brief Enable sensor, Include Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8位字节数据,每一位都代表使能一个功能位,如下表所示:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Y-axis of acceleration.

* @n bit5: X-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: 使能陀螺仪的任意轴,都会自动使能传感器板载温度传感器。

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit, enable temperature, Accel's and gyro's xyz axis.

*/

icg.enableSensor(icg.eAccelAxisXYZ);

//icg.enableSensor(icg.eAccelAxisX|icg.eAccelAxisY|icg.eAccelAxisZ);

/**

* @brief Config of accel's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of accel, unit: g(1g = 9.80665 m/s²).

* @n eFSR_A_2G: The full scale range is ±2g.

* @n eFSR_A_4G: The full scale range is ±4g.

* @n eFSR_A_8G: The full scale range is ±8g.

* @n eFSR_A_16G: The full scale range is ±16g.

* @param bd Set 3-db bandwidth.

* @n eAccel_DLPF_5_1KHZ or 0: 当信号小于或等于5Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_10_1KHZ or 1: 当信号小于或等于10Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_21_1KHZ or 2: 当信号小于或等于21Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_44_1KHZ or 3: 当信号小于或等于44Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_99_1KHZ or 4: 当信号小于或等于99Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_218_1KHZ or 5: 当信号小于或等于218Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_420_1KHZ or 6: 当信号小于或等于420Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_1046_4KHZ or 7: 当信号小于或等于1046Hz时,会出现明显衰减,衰减3-db,内部采样率为4KHz,支持低功耗模式

* @n eAccel_DLPF_55_1KHZ or 8: 当信号小于或等于55Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n eAccel_DLPF_110_1KHZ or 9: 当信号小于或等于110Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

* @param odr: Sets the frequency of waking up the chip to take a sample of accel data – the low power accel Output Data Rate.

* @n eODR_125Hz or 9: The low power accel Output Data Rate: 125Hz

* @n eODR_250Hz or 10: The low power accel Output Data Rate: 250Hz

* @n eODR_500Hz or 11: The low power accel Output Data Rate: 500Hz

* @param lowPowerFlag: Whether to configure the Acceleration to low power mode.

* @n true: Enter low power mode.

* @n false: Not configure the Acceleration to low power mode.(default)

*/

icg.configAccel(icg.eFSR_A_16G, icg.eAccel_DLPF_99_1KHZ);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n 采样率 = 内部采样率/(div+1)

* @n Note: 如果加速度配置为低功耗模式,即configAccel函数的形参lowPowerFlag为true,则采样率必须和configAccel的形参odr输出率相匹配,如下表所示:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n | 支持低功耗模式的bd | eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

icg.setSampleDiv(19);

}

void loop() {

float x, y, z;

sIcg20660SensorData_t accel;

accel.x = icg.getAccelDataX();

accel.y = icg.getAccelDataY();

accel.z = icg.getAccelDataZ();

Serial.print("Accel: unit(g) ");

Serial.print("x: ");Serial.print(accel.x);

Serial.print(",\ty: ");Serial.print(accel.y);

Serial.print(",\tz: ");Serial.println(accel.z);

Serial.print("Accel: unit(m/s2)");

Serial.print("x: ");Serial.print(accel.x*G);

Serial.print(",\ty: ");Serial.print(accel.y*G);

Serial.print(",\tz: ");Serial.println(accel.z*G);

Serial.println();

delay(1000);

}

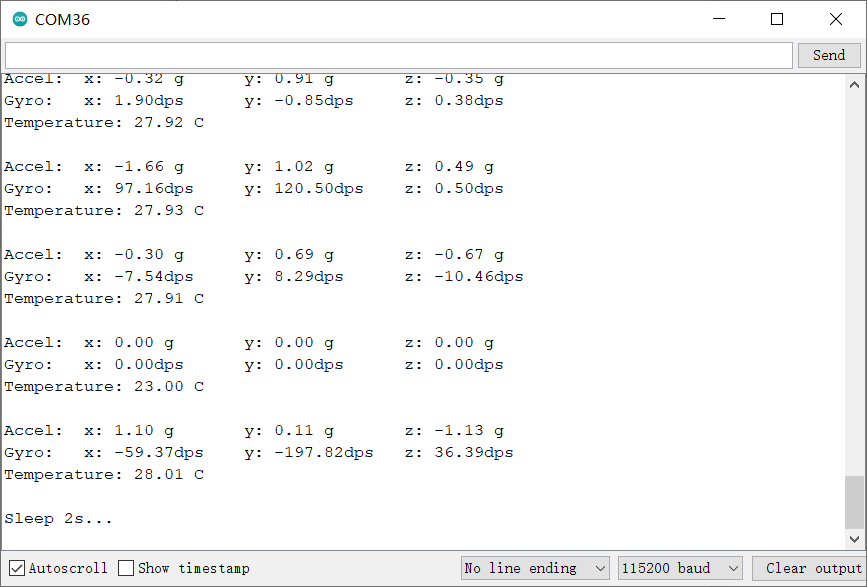

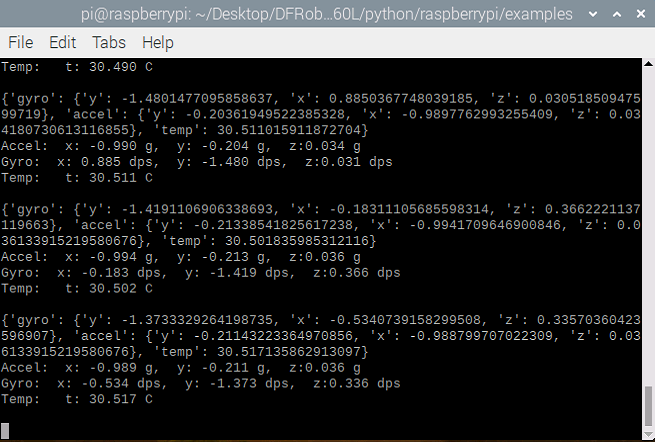

- 结果

样例代码2-读取陀螺仪的x,y,z轴的数据(getGyroData.ino)

- 选择getGyroData.ino

- 烧录程序

/*!

* @file getGyroData.ino

* @brief 获取传感器的陀螺仪的x,y,z轴的数据(此demo不支持FIFO读取模式),单位dps,并将其转换为角速度rad/s。

*

* @n connected table in SPI

* -----------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MISO | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MOSI | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -----------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* ---------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* SDA | connected to SDA of mcu'iic | 21/SDA| SDA | SDA | P20/SDA | 20/SDA |

* SCL | connected to scl of mcu'iic | 22/SCL| SCL | SCL | P19/SCL | 21/SCL |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* ---------------------------------------------------------------------------------------------------

*

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @licence The MIT License (MIT)

* @author [Arya](xue.peng@dfrobot.com)

* @version V1.0

* @data 2021-05-24

* @get from https://www.dfrobot.com

* @url https://github.com/DFRobot/DFRobot_ICG20660L

*/

#include "DFRobot_ICG20660L.h"

#ifdef ARDUINO_BBC_MICROBIT

#define CS_PIN 8 //The CS pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#else

#define CS_PIN 5 //The CS pin of sensor which is connected to the 5 digital io pin of MCU,and also can connected to other pin.

#endif

/**

* @brief The constructor of the ICG20660L sensor using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC icg(/*addr=*/IIC_ADDR_SDO_H, &Wire);

/**

* @brief The constructor of the ICG20660L sensor using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

//DFRobot_ICG20660L_SPI icg(/*csPin=*/CS_PIN, &SPI);

float DPS = 3.1415926/180.0; // unit: 1dps = 3.1415926/180.0rad/s

void setup() {

Serial.begin(115200);

while(!Serial){ //Waiting for USB Serial COM port to open.

}

Serial.print("Initialization sensor...");

/**

* @brief 初始化传感器,初始化后,所有传感器都被关闭,需通过enableSensor打开相应的配置.

* @param mode: Enum variable,from eDataReadMode_t,配置读取传感器数据是从FIFO还是从寄存器。

* @n eRegMode: 配置为从寄存器读取传感器数据

* @n eFIFOMode: 从512字节FIFO读取数据,注意:从FIFO读取,加速度,陀螺仪、温度必须全部使能,且将其内部采样率必须配置成一致。(此demo不支持)

* @return status:

* @n 0 : Initialization sucess.

* @n -1: Interface Initialization failed(IIC or SPI).

* @n -2: 读取设备ID失败,ID不是0x91

*/

while(icg.begin(/*mode=*/icg.eRegMode) != 0){

Serial.println("failed. Please check whether the hardware connection is wrong.");

delay(1000);

Serial.print("Initialization sensor...");

}

Serial.println("done.");

Serial.print("ICG20660L Device ID: 0x");

Serial.println(icg.readID(), HEX);

/**

* @brief Enable sensor, Include Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8位字节数据,每一位都代表使能一个功能位,如下表所示:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: 使能陀螺仪的任意轴,都会自动使能传感器板载温度传感器。

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit, enable temperature, Accel's and gyro's xyz axis.

*/

icg.enableSensor(icg.eGyroAxisXYZ);

//icg.enableSensor(icg.eGyroAxisX|icg.eGyroAxisY|icg.eGyroAxisZ);

/**

* @brief Config of gyro's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of gyro, unit: dps(Degrees per second).

* @n eFSR_G_125DPS: The full scale range is ±125 dps.

* @n eFSR_G_250DPS: The full scale range is ±250 dps.

* @n eFSR_G_500DPS: The full scale range is ±500 dps.

* @param bd Set 3-db bandwidth.

* @n eGyro_DLPF_8173_32KHZ: 当信号等于或大于8173Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_3281_32KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_250_8KHZ: 当信号等于或大于250Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n eGyro_DLPF_176_1KHZ: 当信号等于或大于176Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_92_1KHZ: 当信号等于或大于92Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_3281_8KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

*/

icg.configGyro(icg.eFSR_G_250DPS, icg.eGyro_DLPF_8173_32KHZ);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n 采样率 = 内部采样率/(div+1)

* @n Note: 如果陀螺仪配置为低功耗模式,即configAccel函数的形参lowPowerFlag为true,则采样率必须和configAccel的形参odr输出率相匹配,如下表所示:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n | 支持低功耗模式的bd | eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

icg.setSampleDiv(19);

}

void loop() {

sIcg20660SensorData_t gyro;

float t;

gyro.x = icg.getGyroDataX();

gyro.y = icg.getGyroDataY();

gyro.z = icg.getGyroDataZ();

t = icg.getTemperatureC();

Serial.print("Gyro unit(dps): ");

Serial.print("\tx: ");Serial.print(gyro.x);

Serial.print(", \ty: ");Serial.print(gyro.y);

Serial.print(", \tz: ");Serial.println(gyro.z);

Serial.print("Gyro unit(rad/s): ");

Serial.print("\tx: ");Serial.print(gyro.x*DPS);

Serial.print(", \ty: ");Serial.print(gyro.y*DPS);

Serial.print(", \tz: ");Serial.println(gyro.z*DPS);

Serial.print("Temperature: \t");

Serial.print(t);Serial.println("C\n");

delay(1000);

}

- 结果

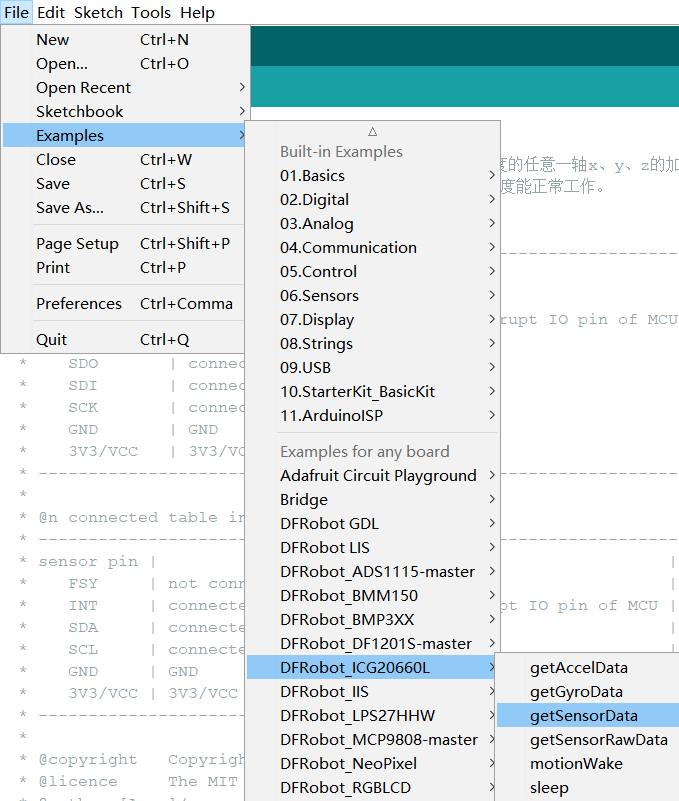

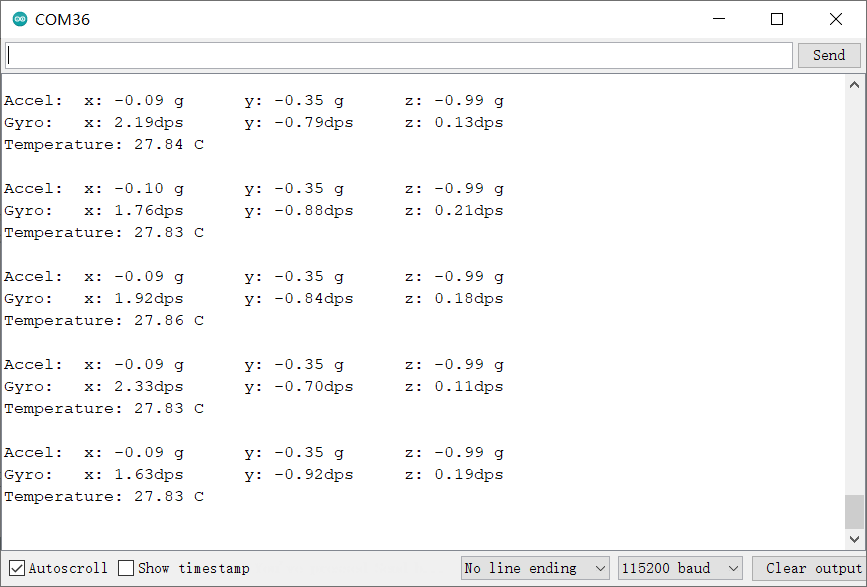

样例代码3-读取陀螺仪、加速度和板载温度数据(getSensorData.ino)

- 选择getSensorData.ino

- 烧录程序

/*!

* @file getSensorData.ino

* @brief 获取传感器的陀螺仪、加速度和板载温度。

* @n connected table in SPI

* -----------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MISO | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MOSI | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -----------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* ---------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* SDA | connected to SDA of mcu'iic | 21/SDA| SDA | SDA | P20/SDA | 20/SDA |

* SCL | connected to scl of mcu'iic | 22/SCL| SCL | SCL | P19/SCL | 21/SCL |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* ---------------------------------------------------------------------------------------------------

*

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @licence The MIT License (MIT)

* @author [Arya](xue.peng@dfrobot.com)

* @version V1.0

* @data 2021-05-24

* @get from https://www.dfrobot.com

* @url https://github.com/DFRobot/DFRobot_ICG20660L

*/

#include "DFRobot_ICG20660L.h"

#ifdef ARDUINO_BBC_MICROBIT

#define CS_PIN 8 //The CS pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#else

#define CS_PIN 5 //The CS pin of sensor which is connected to the 5 digital io pin of MCU,and also can connected to other pin.

#endif

/**

* @brief The constructor of the ICG20660L sensor using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC icg(/*addr=*/IIC_ADDR_SDO_H, &Wire);

/**

* @brief The constructor of the ICG20660L sensor using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

//DFRobot_ICG20660L_SPI icg(/*csPin=*/CS_PIN, &SPI);

void setup() {

Serial.begin(115200);

while(!Serial){ //Waiting for USB Serial COM port to open.

}

Serial.print("Initialization sensor...");

/**

* @brief 初始化传感器,初始化后,所有传感器都被关闭,需通过enableSensor打开相应的配置.

* @param mode: Enum variable,from eDataReadMode_t,配置读取传感器数据是从FIFO还是从寄存器。

* @n eRegMode: 配置为从寄存器读取传感器数据

* @n eFIFOMode: 从512字节FIFO读取数据,注意:从FIFO读取,加速度,陀螺仪、温度必须全部使能,且将其内部采样率必须配置成一致

* @return status:

* @n 0 : Initialization sucess.

* @n -1: Interface Initialization failed(IIC or SPI).

* @n -2: 读取设备ID失败,ID不是0x91

*/

while(icg.begin(/*mode=*/icg.eRegMode) != 0){

Serial.println("failed. Please check whether the hardware connection is wrong.");

delay(1000);

Serial.print("Initialization sensor...");

}

Serial.println("done.");

Serial.print("ICG20660L Device ID: 0x");

Serial.println(icg.readID(), HEX);

/**

* @brief Enable sensor, Include Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8位字节数据,每一位都代表使能一个功能位,如下表所示:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: 使能陀螺仪的任意轴,都会自动使能传感器板载温度传感器。

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit, enable temperature, Accel's and gyro's xyz axis.

*/

icg.enableSensor(icg.eAxisAll);

//icg.enableSensor(icg.eGyroAxisXYZ|icg.eAccelAxisXYZ);

//icg.enableSensor(icg.eGyroAxisX|icg.eGyroAxisY|icg.eGyroAxisZ|icg.eAccelAxisX|icg.eAccelAxisY|icg.eAccelAxisZ);

/**

* @brief Config of gyro's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of gyro, unit: dps(Degrees per second).

* @n eFSR_G_125DPS: The full scale range is ±125 dps.

* @n eFSR_G_250DPS: The full scale range is ±250 dps.

* @n eFSR_G_500DPS: The full scale range is ±500 dps.

* @param bd Set 3-db bandwidth.

* @n eGyro_DLPF_8173_32KHZ: 当信号等于或大于8173Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_3281_32KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_250_8KHZ: 当信号等于或大于250Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n eGyro_DLPF_176_1KHZ: 当信号等于或大于176Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_92_1KHZ: 当信号等于或大于92Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_3281_8KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

*/

icg.configGyro(/*scale=*/icg.eFSR_G_250DPS, /*bd=*/icg.eGyro_DLPF_176_1KHZ);

/**

* @brief Config of accel's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of accel, unit: g(1g = 9.80665 m/s²).

* @n eFSR_A_2G: The full scale range is ±2g.

* @n eFSR_A_4G: The full scale range is ±4g.

* @n eFSR_A_8G: The full scale range is ±8g.

* @n eFSR_A_16G: The full scale range is ±16g.

* @param bd Set 3-db bandwidth.

* @n eAccel_DLPF_5_1KHZ or 0: 当信号小于或等于5Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_10_1KHZ or 1: 当信号小于或等于10Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_21_1KHZ or 2: 当信号小于或等于21Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_44_1KHZ or 3: 当信号小于或等于44Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_99_1KHZ or 4: 当信号小于或等于99Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_218_1KHZ or 5: 当信号小于或等于218Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_420_1KHZ or 6: 当信号小于或等于420Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_1046_4KHZ or 7: 当信号小于或等于1046Hz时,会出现明显衰减,衰减3-db,内部采样率为4KHz,支持低功耗模式

* @n eAccel_DLPF_55_1KHZ or 8: 当信号小于或等于55Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n eAccel_DLPF_110_1KHZ or 9: 当信号小于或等于110Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

* @param odr: Sets the frequency of waking up the chip to take a sample of accel data – the low power accel Output Data Rate.

* @n eODR_125Hz or 9: The low power accel Output Data Rate: 125Hz

* @n eODR_250Hz or 10: The low power accel Output Data Rate: 250Hz

* @n eODR_500Hz or 11: The low power accel Output Data Rate: 500Hz

* @param lowPowerFlag: Whether to configure the Acceleration to low power mode.

* @n true: Enter low power mode.

* @n false: Not configure the Acceleration to low power mode.(default)

*/

icg.configAccel(/*scale=*/icg.eFSR_A_16G, /*bd=*/icg.eAccel_DLPF_218_1KHZ);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n 采样率 = 内部采样率/(div+1)

* @n Note: 如果加速度配置为低功耗模式,即configAccel函数的形参lowPowerFlag为true,则采样率必须和configAccel的形参odr输出率相匹配,如下表所示:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n | 支持低功耗模式的bd | eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

icg.setSampleDiv(19);

}

#define printAxisData(sAxis, str) \

Serial.print(" x: "); \

Serial.print(sAxis.x); \

Serial.print(str); \

Serial.print(" \ty: "); \

Serial.print(sAxis.y); \

Serial.print(str); \

Serial.print(" \tz: "); \

Serial.print(sAxis.z);\

Serial.println(str);

void loop() {

sIcg20660SensorData_t gyro, accel;

float t;

/**

* @brief Get Sensor's accel, gyro and temperature data.

* @param accel: sIcg20660SensorData_t structure pointer which point to accel or NULL.

* @param gyro: sIcg20660SensorData_t structure pointer which point to gyro or NULL.

* @param t: A float pointer which point to temperature or NULL.

*/

icg.getSensorData(&accel, &gyro, &t);

Serial.print("Accel: ");printAxisData(accel, " g");

Serial.print("Gyro: ");printAxisData(gyro, "dps");

Serial.print("Temperature: ");Serial.print(t);Serial.println(" C");

Serial.println();

delay(1000);

}

- 结果

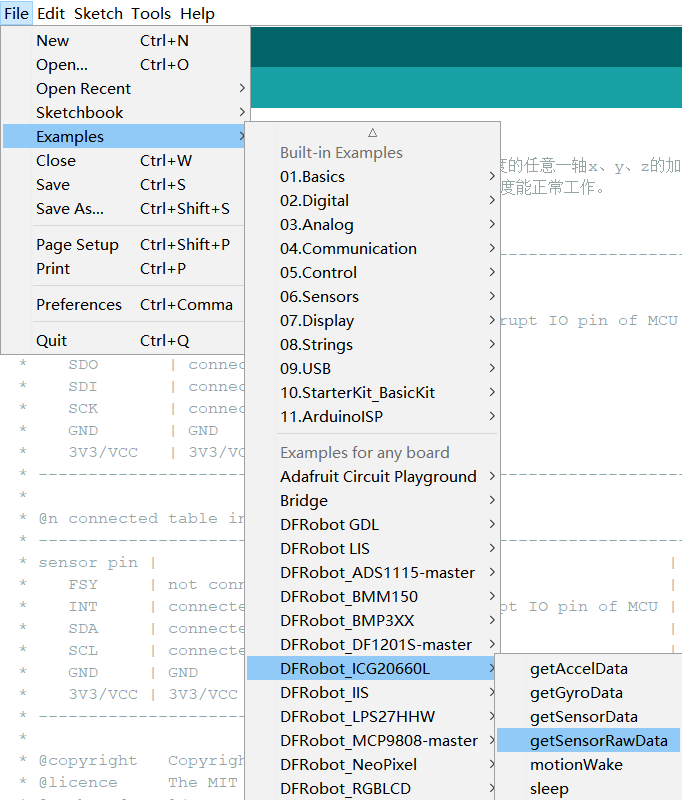

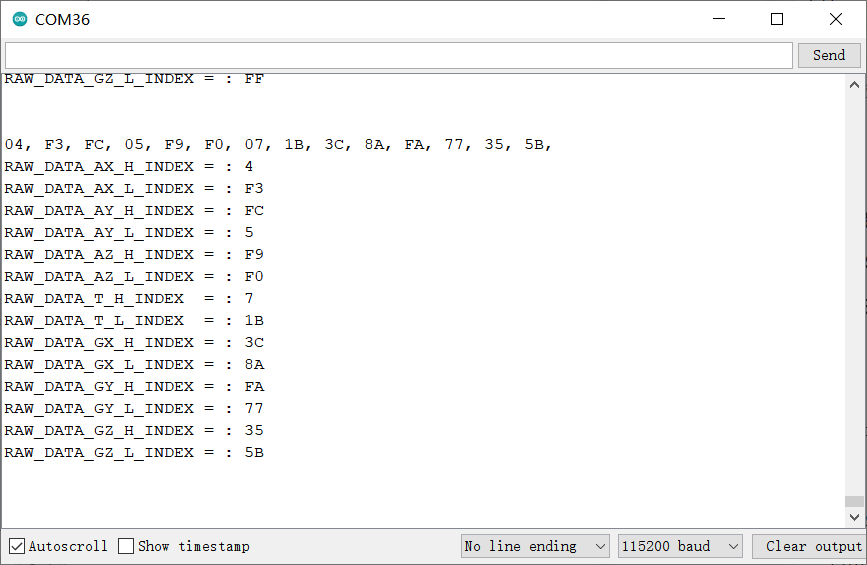

样例代码4-读取加速度,温度、陀螺仪的14字节原始数据(getSensorRawData.ino)

- 选择getSensorRawData.ino

- 烧录程序

/*!

* @file getSensorRawData.ino

* @brief 获取14字节原始数据,分别为加速度X、y、z轴数据,温度、陀螺仪X、y、z轴数据

*

* @n connected table in SPI

* -----------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MISO | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MOSI | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -----------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* ---------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* SDA | connected to SDA of mcu'iic | 21/SDA| SDA | SDA | P20/SDA | 20/SDA |

* SCL | connected to scl of mcu'iic | 22/SCL| SCL | SCL | P19/SCL | 21/SCL |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* ---------------------------------------------------------------------------------------------------

*

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @licence The MIT License (MIT)

* @author [Arya](xue.peng@dfrobot.com)

* @version V1.0

* @data 2021-05-24

* @get from https://www.dfrobot.com

* @url https://github.com/DFRobot/DFRobot_ICG20660L

*/

#include "DFRobot_ICG20660L.h"

#ifdef ARDUINO_BBC_MICROBIT

#define CS_PIN 8 //The CS pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#else

#define CS_PIN 5 //The CS pin of sensor which is connected to the 5 digital io pin of MCU,and also can connected to other pin.

#endif

/**

* @brief The constructor of the ICG20660L sensor using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC icg(/*addr=*/IIC_ADDR_SDO_H, &Wire);

/**

* @brief The constructor of the ICG20660L sensor using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

//DFRobot_ICG20660L_SPI icg(/*csPin=*/CS_PIN, &SPI);

void setup() {

Serial.begin(115200);

while(!Serial){ //Waiting for USB Serial COM port to open.

}

Serial.print("Initialization sensor...");

/**

* @brief 初始化传感器,初始化后,所有传感器都被关闭,需通过enableSensor打开相应的配置.

* @param mode: Enum variable,from eDataReadMode_t,配置读取传感器数据是从FIFO还是从寄存器。

* @n eRegMode: 配置为从寄存器读取传感器数据

* @n eFIFOMode: 从512字节FIFO读取数据,注意:从FIFO读取,加速度,陀螺仪、温度必须全部使能,且将其内部采样率必须配置成一致

* @return status:

* @n 0 : Initialization sucess.

* @n -1: Interface Initialization failed(IIC or SPI).

* @n -2: 读取设备ID失败,ID不是0x91

*/

while(icg.begin(/*mode=*/icg.eRegMode) != 0){

Serial.println("failed. Please check whether the hardware connection is wrong.");

delay(1000);

Serial.print("Initialization sensor...");

}

Serial.println("done.");

Serial.print("ICG20660L Device ID: 0x");

Serial.println(icg.readID(), HEX);

/**

* @brief Enable sensor, Include Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8位字节数据,每一位都代表使能一个功能位,如下表所示:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: 使能陀螺仪的任意轴,都会自动使能传感器板载温度传感器。

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit, enable temperature, Accel's and gyro's xyz axis.

*/

icg.enableSensor(icg.eAxisAll);

//icg.enableSensor(icg.eGyroAxisXYZ|icg.eAccelAxisXYZ);

//icg.enableSensor(icg.eGyroAxisX|icg.eGyroAxisY|icg.eGyroAxisZ|icg.eAccelAxisX|icg.eAccelAxisY|icg.eAccelAxisZ);

/**

* @brief Config of gyro's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of gyro, unit: dps(Degrees per second).

* @n eFSR_G_125DPS: The full scale range is ±125 dps.

* @n eFSR_G_250DPS: The full scale range is ±250 dps.

* @n eFSR_G_500DPS: The full scale range is ±500 dps.

* @param bd Set 3-db bandwidth.

* @n eGyro_DLPF_8173_32KHZ: 当信号等于或大于8173Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_3281_32KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为32KHz

* @n eGyro_DLPF_250_8KHZ: 当信号等于或大于250Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n eGyro_DLPF_176_1KHZ: 当信号等于或大于176Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_92_1KHZ: 当信号等于或大于92Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eGyro_DLPF_3281_8KHZ: 当信号等于或大于3281Hz时,会出现明显衰减,衰减3-db,内部采样率为8KHz

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

*/

icg.configGyro(/*scale=*/icg.eFSR_G_250DPS, /*bd=*/icg.eGyro_DLPF_176_1KHZ);

/**

* @brief Config of accel's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of accel, unit: g(1g = 9.80665 m/s²).

* @n eFSR_A_2G: The full scale range is ±2g.

* @n eFSR_A_4G: The full scale range is ±4g.

* @n eFSR_A_8G: The full scale range is ±8g.

* @n eFSR_A_16G: The full scale range is ±16g.

* @param bd Set 3-db bandwidth.

* @n eAccel_DLPF_5_1KHZ or 0: 当信号小于或等于5Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_10_1KHZ or 1: 当信号小于或等于10Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_21_1KHZ or 2: 当信号小于或等于21Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_44_1KHZ or 3: 当信号小于或等于44Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_99_1KHZ or 4: 当信号小于或等于99Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_218_1KHZ or 5: 当信号小于或等于218Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_420_1KHZ or 6: 当信号小于或等于420Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_1046_4KHZ or 7: 当信号小于或等于1046Hz时,会出现明显衰减,衰减3-db,内部采样率为4KHz,支持低功耗模式

* @n eAccel_DLPF_55_1KHZ or 8: 当信号小于或等于55Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n eAccel_DLPF_110_1KHZ or 9: 当信号小于或等于110Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

* @param odr: Sets the frequency of waking up the chip to take a sample of accel data – the low power accel Output Data Rate.

* @n eODR_125Hz or 9: The low power accel Output Data Rate: 125Hz

* @n eODR_250Hz or 10: The low power accel Output Data Rate: 250Hz

* @n eODR_500Hz or 11: The low power accel Output Data Rate: 500Hz

* @param lowPowerFlag: Whether to configure the Acceleration to low power mode.

* @n true: Enter low power mode.

* @n false: Not configure the Acceleration to low power mode.(default)

*/

icg.configAccel(/*scale=*/icg.eFSR_A_16G, /*bd=*/icg.eAccel_DLPF_218_1KHZ);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n 采样率 = 内部采样率/(div+1)

* @n Note: 如果加速度配置为低功耗模式,即configAccel函数的形参lowPowerFlag为true,则采样率必须和configAccel的形参odr输出率相匹配,如下表所示:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n | 支持低功耗模式的bd | eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

icg.setSampleDiv(19);

}

void loop() {

uint8_t rawData[RAW_DATA_LENGTH];

/**

* @brief Get 14 bytes raw data, include accel, gyro, and temperature.

* @param data: 存放14字节原始数据的buffer。

* @n The first byte of data : Acceleration X-axis high byte data.

* @n The second byte of data: Acceleration X-axis low byte data.

* @n The third byte of data : Acceleration Y-axis high byte data.

* @n The 4th byte of data : Acceleration Y-axis low byte data.

* @n The 5th byte of data : Acceleration Z-axis high byte data.

* @n The 6th byte of data : Acceleration Z-axis low byte data.

* @n The 7th byte of data : Temperature high byte data.

* @n The 8th byte of data : Temperature low byte data.

* @n The 9th byte of data : Gyro X-axis high byte data.

* @n The 10th byte of data : Gyro X-axis low byte data.

* @n The 11th byte of data : Gyro Y-axis high byte data.

* @n The 12th byte of data : Gyro Y-axis low byte data.

* @n The 13th byte of data : Gyro Z-axis high byte data.

* @n The 14th byte of data : Gyro Z-axis low byte data.

* @n Note: You can use RAW_DATA_LENGTH to creat data Arrya, and you can use

* @n RAW_DATA_AX_H_INDEX, RAW_DATA_AX_L_INDEX, RAW_DATA_AY_H_INDEX, RAW_DATA_AY_L_INDEX, RAW_DATA_AZ_H_INDEX, RAW_DATA_AZ_L_INDEX,

* @n RAW_DATA_T_H_INDEX, RAW_DATA_T_L_INDEX,RAW_DATA_GX_H_INDEX, RAW_DATA_GX_L_INDEX,

* @n RAW_DATA_GY_H_INDEX, RAW_DATA_GY_L_INDEX, RAW_DATA_GZ_H_INDEX, RAW_DATA_GZ_L_INDEX or 0~13 to index data array.

* @param len: The length of data array.

*/

icg.getRawData(rawData,RAW_DATA_LENGTH);

for(int i = 0; i < RAW_DATA_LENGTH; i++){

if(rawData[i] < 16){

Serial.print("0");

}

Serial.print(rawData[i],HEX);

Serial.print(", ");

}

Serial.println();

Serial.print("RAW_DATA_AX_H_INDEX = : ");Serial.println(rawData[RAW_DATA_AX_H_INDEX],HEX);

Serial.print("RAW_DATA_AX_L_INDEX = : ");Serial.println(rawData[RAW_DATA_AX_L_INDEX],HEX);

Serial.print("RAW_DATA_AY_H_INDEX = : ");Serial.println(rawData[RAW_DATA_AY_H_INDEX],HEX);

Serial.print("RAW_DATA_AY_L_INDEX = : ");Serial.println(rawData[RAW_DATA_AY_L_INDEX],HEX);

Serial.print("RAW_DATA_AZ_H_INDEX = : ");Serial.println(rawData[RAW_DATA_AZ_H_INDEX],HEX);

Serial.print("RAW_DATA_AZ_L_INDEX = : ");Serial.println(rawData[RAW_DATA_AZ_L_INDEX],HEX);

Serial.print("RAW_DATA_T_H_INDEX = : ");Serial.println(rawData[RAW_DATA_T_H_INDEX],HEX);

Serial.print("RAW_DATA_T_L_INDEX = : ");Serial.println(rawData[RAW_DATA_T_L_INDEX],HEX);

Serial.print("RAW_DATA_GX_H_INDEX = : ");Serial.println(rawData[RAW_DATA_GX_H_INDEX],HEX);

Serial.print("RAW_DATA_GX_L_INDEX = : ");Serial.println(rawData[RAW_DATA_GX_L_INDEX],HEX);

Serial.print("RAW_DATA_GY_H_INDEX = : ");Serial.println(rawData[RAW_DATA_GY_H_INDEX],HEX);

Serial.print("RAW_DATA_GY_L_INDEX = : ");Serial.println(rawData[RAW_DATA_GY_L_INDEX],HEX);

Serial.print("RAW_DATA_GZ_H_INDEX = : ");Serial.println(rawData[RAW_DATA_GZ_H_INDEX],HEX);

Serial.print("RAW_DATA_GZ_L_INDEX = : ");Serial.println(rawData[RAW_DATA_GZ_L_INDEX],HEX);

Serial.println('\n');

delay(1000);

}

- 结果

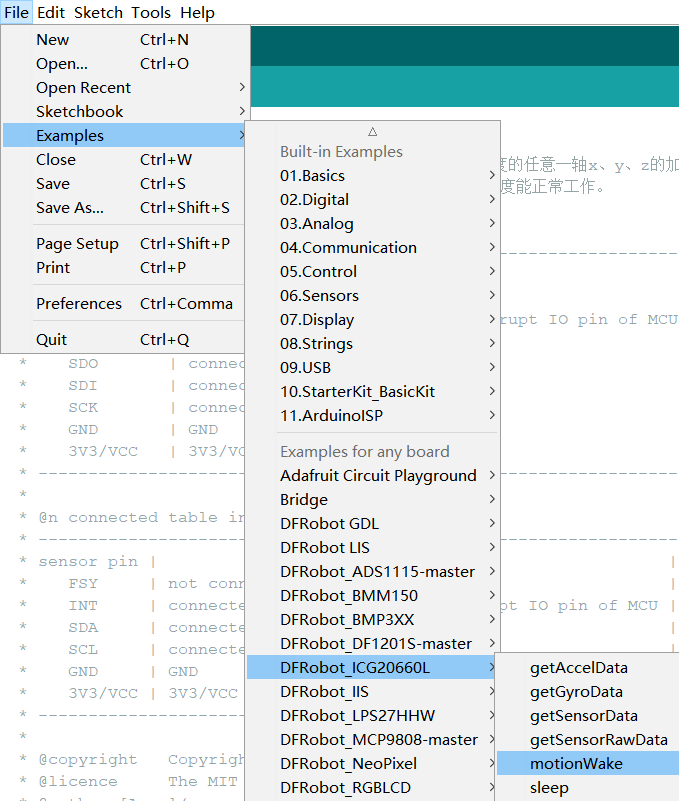

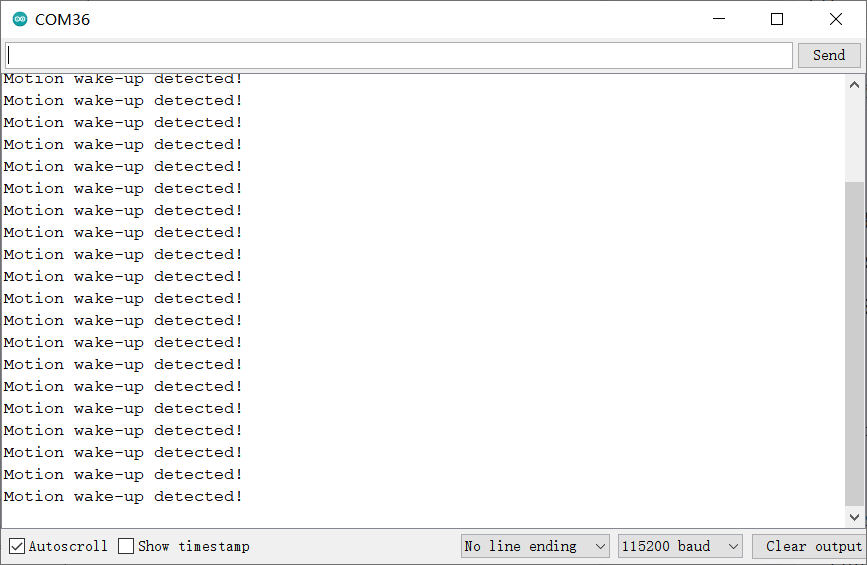

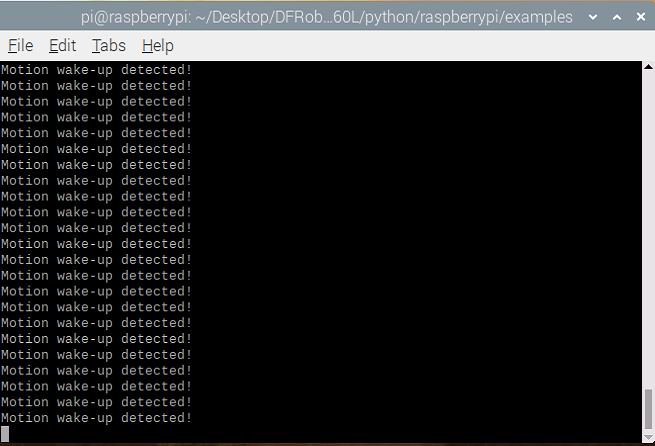

样例代码5-中断功能(motionWake.ino)

- 选择motionWake.ino

- 烧录程序

/*!

* @file motionWake.ino

* @brief 设置加速度中断唤醒阈值,在低功耗模式下,如果加速度的任意一轴x、y、z的加速度达到此阈值,传感器

* 的中断输出引脚INT将产生一个中断信号。低功耗模式下只有加速度能正常工作。

*

* @n connected table in SPI

* ---------------------------------------------------------------------------------------------------------------------

* Sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | connected to the external interrupt IO pin of MCU | 2/D9 | 2/D5 | 2 | P9 | 2 |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MI | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MO | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* ---------------------------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* -------------------------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | connected to the external interrupt IO pin of MCU | 2/D9 | 2/D5 | 2 | P9 | 2 |

* SDA | connected to SDA of mcu'iic | 21/SDA| SDA | SDA | P20/SDA | 20/SDA |

* SCL | connected to scl of mcu'iic | 22/SCL| SCL | SCL | P19/SCL | 21/SCL |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -------------------------------------------------------------------------------------------------------------------

*

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @licence The MIT License (MIT)

* @author [Arya](xue.peng@dfrobot.com)

* @version V1.0

* @data 2021-06-01

* @get from https://www.dfrobot.com

* @url https://github.com/DFRobot/DFRobot_ICG20660L

*/

#include "DFRobot_ICG20660L.h"

#if defined(ARDUINO_BBC_MICROBIT)

#define CS_PIN 8 //The CS pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#define INT_PIN 9 //The INT pin of sensor which is connected to the 8 digital io pin of micro:bit,and also can connected to other pin.

#else

#define CS_PIN 5 //The CS pin of sensor which is connected to the 5 digital io pin of MCU,and also can connected to other pin.

#define INT_PIN 2 //The INT pin of sensor which is connected to the 2 digital io pin of MCU,and also can connected to other pin.

#endif

/**

* @brief The constructor of the ICG20660L sensor using IIC communication.

* @param addr: 7-bit IIC address, controlled by SDO pin.

* @n IIC_ADDR_SDO_H or 0x69: SDO pull high.(default)

* @n IIC_ADDR_SDO_L or 0x68: SDO pull down.

* @param pWire: TwoWire class pointer.

*/

DFRobot_ICG20660L_IIC icg(/*addr=*/IIC_ADDR_SDO_H, &Wire);

/**

* @brief The constructor of the ICG20660L sensor using SPI communication.

* @param csPin: SPI chip select pin, connected to IO pin of MCU.

* @param spi: SPIClass class pointer.

*/

//DFRobot_ICG20660L_SPI icg(/*csPin=*/CS_PIN, &SPI);

bool irqFlag = false;

void fun(){

irqFlag = true;

}

void setup() {

Serial.begin(115200);

while(!Serial){ //Waiting for USB Serial COM port to open.

}

Serial.print("Initialization sensor...");

/**

* @brief 初始化传感器,初始化后,所有传感器都被关闭,需通过enableSensor打开相应的配置.

* @param mode: Enum variable,from eDataReadMode_t,配置读取传感器数据是从FIFO还是从寄存器。

* @n eRegMode: 配置为从寄存器读取传感器数据

* @n eFIFOMode: 从512字节FIFO读取数据,注意:从FIFO读取,加速度,陀螺仪、温度必须全部使能,且将其内部采样率必须配置成一致。(此demo不支持)

* @return status:

* @n 0 : Initialization sucess.

* @n -1: Interface Initialization failed(IIC or SPI).

* @n -2: 读取设备ID失败,ID不是0x91

*/

while(icg.begin(/*mode=*/icg.eRegMode) != 0){

Serial.println("failed. Please check whether the hardware connection is wrong.");

delay(1000);

Serial.print("Initialization sensor...");

}

Serial.println("done.");

Serial.print("ICG20660L Device ID: 0x");

Serial.println(icg.readID(), HEX);

/**

* @brief Enable sensor, Include Accel of xyz axis, Gyro of xyz, temperature.

* @param bit: 8位字节数据,每一位都代表使能一个功能位,如下表所示:

* @n -------------------------------------------------------------------------------------------------------------------

* @n | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

* @n -------------------------------------------------------------------------------------------------------------------

* @n | reserve | reserve | eAccelAxisX | eAccelAxisY | eAccelAxisZ | eGyroAxisX | eGyroAxisY | eGyroAxisZ |

* @n | | eAccelAxisXYZ | eGyroAxisXYZ |

* @n | | eAxisAll |

* @n -------------------------------------------------------------------------------------------------------------------

* @n bit0: Z-axis of gyro and temperature.

* @n bit1: Y-axis of gyro and temperature.

* @n bit2: X-axis of gyro and temperature.

* @n bit3: Z-axis of acceleration.

* @n bit4: Z-axis of acceleration.

* @n bit5: Z-axis of acceleration.

* @n bit6: reserve.

* @n bit7: reserve.

* @n Note: 使能陀螺仪的任意轴,都会自动使能传感器板载温度传感器。

* @n eGyroAxisZ: The bit0 of the bit, enable gyro's z axis and temperature.

* @n eGyroAxisY: The bit1 of the bit, enable gyro's y axis and temperature.

* @n eGyroAxisX: The bit2 of the bit, enable gyro's X axis and temperature.

* @n eAccelAxisZ: The bit3 of the bit, enable accel's z axis.

* @n eAccelAxisY: The bit4 of the bit, enable Accel's y axis.

* @n eAccelAxisX: The bit5 of the bit, enable Accel's X axis.

* @n eGyroAxisXYZ or eGyroAxisX|eGyroAxisY|eGyroAxisZ: The bit0/bit1/bit2 of the bit, enable gyro's xyz axis and temperature.

* @n eAccelAxisXYZ or eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit3/bit4/bit5 of the bit, enable Accel's xyz axis.

* @n eAxisAll or eGyroAxisX|eGyroAxisY|eGyroAxisZ|eAccelAxisX|eAccelAxisY|eAccelAxisZ: The bit0/bit1/bit2/bit3/bit4/bit5 of the bit, enable temperature, Accel's and gyro's xyz axis.

*/

icg.enableSensor(icg.eAccelAxisXYZ);

//icg.enableSensor(icg.eAccelAxisX|icg.eAccelAxisY|icg.eAccelAxisZ);

/**

* @brief Config of accel's full scale 、dlpf bandwidth and internal sample rate.

* @param scale The full scale of accel, unit: g(1g = 9.80665 m/s²).

* @n eFSR_A_2G: The full scale range is ±2g.

* @n eFSR_A_4G: The full scale range is ±4g.

* @n eFSR_A_8G: The full scale range is ±8g.

* @n eFSR_A_16G: The full scale range is ±16g.

* @param bd Set 3-db bandwidth.

* @n eAccel_DLPF_5_1KHZ or 0: 当信号小于或等于5Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_10_1KHZ or 1: 当信号小于或等于10Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_21_1KHZ or 2: 当信号小于或等于21Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_44_1KHZ or 3: 当信号小于或等于44Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_99_1KHZ or 4: 当信号小于或等于99Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz

* @n eAccel_DLPF_218_1KHZ or 5: 当信号小于或等于218Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_420_1KHZ or 6: 当信号小于或等于420Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,支持低功耗模式

* @n eAccel_DLPF_1046_4KHZ or 7: 当信号小于或等于1046Hz时,会出现明显衰减,衰减3-db,内部采样率为4KHz,支持低功耗模式

* @n eAccel_DLPF_55_1KHZ or 8: 当信号小于或等于55Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n eAccel_DLPF_110_1KHZ or 9: 当信号小于或等于110Hz时,会出现明显衰减,衰减3-db,内部采样率为1KHz,仅支持低功耗模式

* @n 注意:当陀螺仪和加速度都使能的时候,如果通过FIFO读取传感器数据,必须保证陀螺仪和加速度的内部采样率一致

* @param odr: Sets the frequency of waking up the chip to take a sample of accel data – the low power accel Output Data Rate.

* @n eODR_125Hz or 9: The low power accel Output Data Rate: 125Hz

* @n eODR_250Hz or 10: The low power accel Output Data Rate: 250Hz

* @n eODR_500Hz or 11: The low power accel Output Data Rate: 500Hz

* @param lowPowerFlag: Whether to configure the Acceleration to low power mode.

* @n true: Enter low power mode.

* @n false: Not configure the Acceleration to low power mode.(default)

*/

icg.configAccel(icg.eFSR_A_16G, icg.eAccel_DLPF_1046_4KHZ, icg.eODR_500Hz, true);

/**

* @brief Set sample rate divider.

* @param div Sample rate divider, the range is 0~255.

* @n 采样率 = 内部采样率/(div+1)

* @n Note: 如果加速度配置为低功耗模式,即configAccel函数的形参lowPowerFlag为true,则采样率必须和configAccel的形参odr输出率相匹配,如下表所示:

* @n ----------------------------------------------------------------------------

* @n | configAccel | setSampleDiv |

* @n ----------------------------------------------------------------------------|

* @n | bd | odr | lowPowerFlag | div |

* @n ----------------------------------------------------------------------------|

* @n | X | X | false | 0~255 |

* @n ----------------------------------------------------------------------------|

* @n | | eODR_125Hz | true | 7 |

* @n | |-----------------------------------------------|

* @n | 支持低功耗模式的bd | eODR_250Hz | true | 3 |

* @n | |-----------------------------------------------|

* @n | | eODR_500Hz | true | 1 |

* @n |---------------------------------------------------------------------------|

*/

icg.setSampleDiv(1);

/**

* @brief 设置触发加速度传感器唤醒运动中断时,INT引脚的电平极性。

* @param polarity: 触发唤醒运动时,传感器INT引脚的电平信号。

* @n HIGH: INT引脚初始信号为LOW,当产生加速度唤醒运动时,INT引脚电平信号将变为HIGH,需要调用readINTStatus函数,才能清除该信号,重新恢复初始信号。

* @n LOW: INT引脚初始信号为HIGH,当产生加速度唤醒运动时,INT引脚电平信号将变为LOW,需要调用readINTStatus函数,才能清除该信号,重新恢复初始信号。

* @n Note: 触发加速度唤醒运动后,如果不调用readINTStatus函数清除该标志,INT引脚将一直保持触发运动时的电平极性。

*/

icg.setINTPinMotionTriggerPolarity(/*polarity =*/LOW);

/**

* @brief Set the threshold value for the Wake on Motion Interrupt for accelerometer.

* @param level: WoM thresholds are expressed in fixed “mg” independent of the selected Range [0g : 1g]; Resolution 1g/256=~3.9mg

* @n level = 0~255

* @return Actul WoM thresholds, unit : g re_value = (level * 3.9)/1000 g

*/

icg.setWakeOnMotionThresholdForAccel(100);/*rate = 100*3.9/1000 g = 0.39g*/

pinMode(INT_PIN,INPUT);

/**

* @brief Enable the external interrupt pin of MCU.

* @param pin: The external pin of MCU.

* @n Mega2560: The external pin is 2、3、21、20、19、18.

* @n microbit: The external pin is 0~20(P0-P20)

* @n ESP32, ESP8266, M0: The external pin is all digital Pin and analog pin.

* @param fun: Pointer to guide interrupt service function.

* @param mode: Interrupt trigger mode.

* @n LOW: Low level trigger.

* @n HIGH: HIGH level trigger

* @n RISING: Rising edge trigger

* @n FALLING: Falling edge trigger

* @n CHANGE: Double edge transition trigger

*/

attachInterrupt(/*pin=*/digitalPinToInterrupt(INT_PIN),/*fun=*/fun,/*mode =*/FALLING);

}

void loop() {

uint8_t status;

if(irqFlag || (digitalRead(INT_PIN) == icg.getINTPinMotionTriggerPolarity())){

irqFlag = false;

/**

* @brief Read interrupt status register, and clear INT pin's interrupt signal.

* @return Interrupt status register value.

* @n INT_STATUS register:addr:0x3A,acess:rw

* @n ------------------------------------------------------------------------------------

* @n | b7 | b6 | b5 | b4 | b3 | b2 | b1 | b0 |

* @n ------------------------------------------------------------------------------------

* @n | WOM_XYZ_INT | FIFO_OFLOW_INT | rsv | DATA_RDY_INT |

* @n ------------------------------------------------------------------------------------

* @n DATA_RDY_INT : This bit automatically sets to 1 when a Data Ready interrupt is generated. The bit clears to 0 after the register has been read.

* @n rsv : reserve

* @n FIFO_OFLOW_INT: This bit automatically sets to 1 when a FIFO buffer overflow has been generated. The bit clears to 0 after the register has been read.

* @n WOM_XYZ_INT : These bits automatically set to a non-zero number when the X-axis,Y-axis or Z-axis of accelerometer which trigger WOM(wake on motion)

* @n interrupt.Cleared on Read.

*/

status = icg.readINTStatus();

if(status & ICG20660L_WOM_XYZ_INT){

Serial.println("Motion wake-up detected!");

}else{

Serial.println("Error!");

}

}

}

- 结果

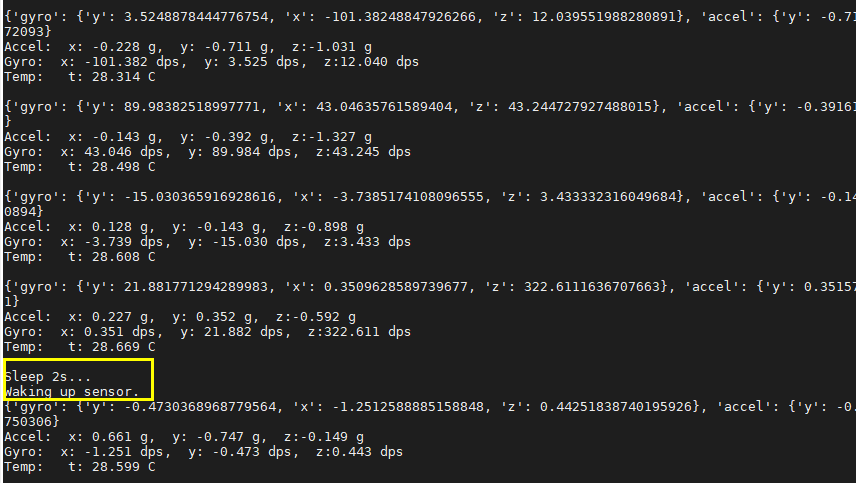

样例代码6-睡眠唤醒功能(sleep.ino)

- 选择sleep.ino

- 烧录程序

/*!

* @file sleep.ino

* @brief 采集20次传感器数据后,控制传感器睡眠2s,此时传感器进入低功耗模式,陀螺仪和加速度,将不会工作,再唤醒。

*

* @n connected table in SPI

* -----------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |

* FSY | not connected, floating | X | X | X | X | X |

* INT | not connected, floating | X | X | X | X | X |

* CS | connected to the IO pin of MCU | 5/D8 | 5/D6 | 5 | P8 | 5 |

* SDO | connected to miso of mcu'spi |19/MISO| MISO | MISO | P14/MISO | 50/MISO |

* SDI | connected to mosi of mcu'spi |23/MOSI| MOSI | MOSI | P15/MOSI | 51/MOSI |

* SCK | connected to sck of mcu'spi |18/SCK | SCK | SCK | P13/SCK | 52/SCK |

* GND | GND | GND | GND | GND | GND | GND |

* 3V3/VCC | 3V3/VCC | 3V3 | 3V3 | 3V3 | 3V3 | 5V |

* -----------------------------------------------------------------------------------------------------

*

* @n connected table in IIC

* ---------------------------------------------------------------------------------------------------

* sensor pin | MCU | ESP32 | ESP8266 | M0 | micro:bit | Mega2560 |